Kassu Jilcha* and Helina Assefa

School of Mechanical and Industrial Engineering, Addis Ababa Institute of Technology, Addis Ababa University, Addis Ababa, Ethiopia

*Corresponding Author: Kassu Jilcha, School of Mechanical and Industrial Engineering, Addis Ababa Institute of Technology, Addis Ababa University, Addis Ababa, Ethiopia.

Received: January 11, 2020; Published: February 10, 2020

Citation: Kassu Jilcha and Helina Assefa. “Evaluation of Musculoskeletal Disorders Risk Factors in Panting: A Case Study of Akaki Basic Metal Industry Painters”. Acta Scientific Paediatrics 3.3 (2020):18-23.

The purpose of this study is to investigate and propose of ergonomic conditions of manual spray painting in the manufacturing industry have been studied. Manual spray painting is despite rationalizations quite common in the Akiaki basic metal industry. Observation and medical record with spray painters showed that they had higher prevalence of musculoskeletal symptoms in their right shoulder compared with other workers with manual work. A majority of the spray painters painted work-pieces lying on a work-table. A majority of these painters abduct the right upper-arm so much when painting the horizontal surface of the work-piece that they risk supraspinatus tendinitis. The upper-arm abduction when painting horizontal surfaces could be decreased without introducing new ergonomic disadvantages by installing work-tables with powered height control or possibly also by changing the geometry of the spray gun. Gripping the spray gun trigger was for some of the painters identified as causing a high risk for WMSD in the wrist. Lower spray gun trigger force would improve the situation. This could be done by the users in several ways, such as greasing the trigger mechanism and/or decreasing the spring pressure on the fluid needle.

Keywords: Work-Related Muscular-Skeletal Disorders; PMSDs

Ergonomics is the scientific discipline concerned with the understanding of interactions among humans and other elements of a system, and the profession that applies theory, principles, data and methods to design in order to optimize human well-being and overall system performance Proper ergonomic design is necessary to prevent repetitive strain injuries and other musculoskeletal disorders, which can develop over time and can lead to long-term disability [1]. The improvement of musculoskeletal health at work is one of the most important objectives of ergonomics According to the International Ergonomics Association (IEA, 2003) Physical ergonomics issues include working postures, materials handling, repetitive movements, Work-related musculoskeletal disorders, workplace layout, safety and health Musculoskeletal health can be maintained by controlling for risk factors. Biomechanical Hazards, genetic predisposition, morphological disadvantages, all interact in the precipitation of work-related musculoskeletal injuries, but it is only Feasible to control for the biomechanical and psychosocial factors Physical exertion in the workplace can result in the precipitation of work-related musculoskeletal Injuries. Studies have shown that posture, range of motion, force repetition (OML, 2011). The goal of ergonomics is to maximize the productivity and efficiency and minimize human suffering due to accidents or chronic excessive stress. An ergonomics program can be as complex as the design of an entire manufacturing plant, or as simple as the “quickfix” adjustment of a chair height [1]. In the processes involved in paint manufacture (such as mixing, milling, and shearing) workers are exposed to organic solvents that may cause a variety of symptoms, including transient symptoms of the central nervous system such as euphoria, headache, and dizziness at low or moderate concentrations and serious symptoms such as fainting and respiratory and circulatory failure at high concentrations [2]. The main objective of this study is to assess the exposure level to PMSDs risks and to determine the MSDs occurrence among painters. Through this the specific objectives are Analyzing the existing situation of painter’s section that exposes the painters to WMSDs risks; Ensuring worker safety, worker health and worker productivity by Reduce absenteeism; causes of MSDs; Improve worker safety and Participate in your employer’s ergonomics program. Industries increasingly require higher production rates and advances in technology to remain competitive and stay in business. As a result, jobs today can involve. Frequent lifting, carrying, and pushing or pulling loads without help from other workers or devices; Increasing specialization that requires the worker to perform only one function or movement for a long period of time or day after day, working more than 8 hours a day, working at a quicker pace of work, such as faster assembly line speeds and Having tighter grips when using tools (Sanchez, 2015). The scope of ergonomics in manufacturing industries include but not limited to pushing and drawing of loads, physical work load, staff posture at work, man-machine interaction, noise, visibility, environmental stress, analysis of human capabilities and weaknesses, fatigue, dynamic forces acting on the human body while at work, the tools used by workers to perform various tasks, etc. Godwin and observed that work-related health problems are experienced by workers across all types of jobs and work sectors, and to many, it has become a fact of life.” However, they explained that some types of work groups seem to be particularly at higher risk Identifying the risk factors in a manufacturing company is fundamental in eliminating (Okpala, 2013). The ability of manufacturing companies to ergonomically design conducive shop floors and plants that enhance good health by allowing reduced motions, better posture and less exertion will lead to more effective and productive work force, as well as the production of high quality products with reduced defects. According to Middles worth another importance of ergonomics is production cost reduction; this is because a properly designed ergonomics friendly workstation will drastically reduce all risk factors that may lead to fatigue, strain, injuries, musculoskeletal disorders, as well as other exorbitant indirect costs (Marilyn and Andrew, 2014). When a worker is exposed to MSD risk factors, they begin to fatigue. When fatigue outruns their body’s recovery system, they develop a musculoskeletal imbalance. Over time, as fatigue continues to outrun recovery and the musculoskeletal imbalance persists, a musculoskeletal disorder develops. These risk factors can be broken up into two categories and individual-related risk factors. Repetition is excessive repetition of movements can imitate tendons and increase pressure on nerves Aback ward postures is position that stretch physical limits can compress nerves and imitate tendons Static postures is positions that a worker must hold for long periods of time can restrict blood flow and damage muscles Quick motions is increased speed or acceleration when bending and twitting can increase the amount of force exerted on body. Compression or contact stress is Grasping edges like tool handles can concentrate force on small areas of the body reduce blood flow and nerve transmission and damage tendons and tendon sheaths Vibration is excessive vibration from tools can decrease blood flow damage nerves and contribute to muscle fatigue whole body vibration can affect skeletal muscles and cause low-back pain Cold temperatures is working in cold temperatures can adversely affect a workers coordination and manual dexterity and cause a worker to use more force than necessary to perform a task force is exerting excessive force can cause a variety of injuries MSD hazards are general classified into three categories; biomechanical hazards, additional hazards, and individual hazards (Middlesworth, 2015). Paint products are widely used in industry to provide sur- face coating for protection against corrosion, for appearance as electrical insulation, for fire retardation and for other special purposes. Paints can be applied by a variety of processes including brush, roller, dip, flow, conventional air spray, airless spray, disk spraying and powder coating fainting and respiratory and circulatory failure at high concentrations in the processes involved in paint manufacture (such as mixing, milling, and shearing) workers are exposed to organic solvents that may cause a variety of symptoms, including transient symptoms of the central nervous system such as euphoria, headache, and dizziness at low or moderate concentrations Long-term exposure may cause damage to the Central Nervous System (CNS), such as cognitive and emotional deficits. In particular, solvent related chronic encephalopathy (SRCE) has been described in several studies. Toxic effects of organic solvents were reported to harm liver, kidney and skin. Occupational exposure to mixtures of organic solvents has been evaluated in many activities, such as pain- ting, paint spraying, floor-laying, shoe making, laundries, graffiti removers, etc. (Aida Abd, Hamid Hassan, 2013). Organic solvents application grew to be wide and diverse in both developed and developing countries. The health effects of organic solvents have been known for more than a century. The introduction of chlorinated solvents in the led to reports of toxicity. Although solvents number in the thousands, only a few have been tested for neurotoxicity. The advent of industry has increased the need for different solvents. While only a few organic solvents were used at the turn of the last century, their number has today increased to several hundreds. Although the primary concern about their usage used to be related to their causing fire and explosion, their toxicological properties have to be considered as well. The most important toxicological properties of organic solvents are their ability to evaporate and to dissolve fats. By dissolving fats, organic solvents can damage hematopoietic tissue [3-10].

To accomplish the objective of the research, the researcher has used different methods while gathering information. The data of the study relies both from primary and secondary sources of data, believed to be the major sources of collecting information. The primary data are collected through direct observation and from the medical data of the industry that found from the medical report of the company in addition to this, direct observation is held on foundry of ABMI (Akaki Basic Metal Industry) to critically observe and analyze the cause of the musculoskeletal disorder among each worker of the industry.

The secondary sources of data that the researcher used are internets, journals, senior thesis work and other relevant books. Complete literature reviews or survey have been conducted regarding the concept of musculoskeletal disorder among welder. After gathering the required data, the data is analyzed by comparing with different research books and literature that wrote in musculoskeletal disorder that happen in the panting area of workers. Reviews or survey have been conducted regarding the concept of musculoskeletal disorder among painter and spray painter.

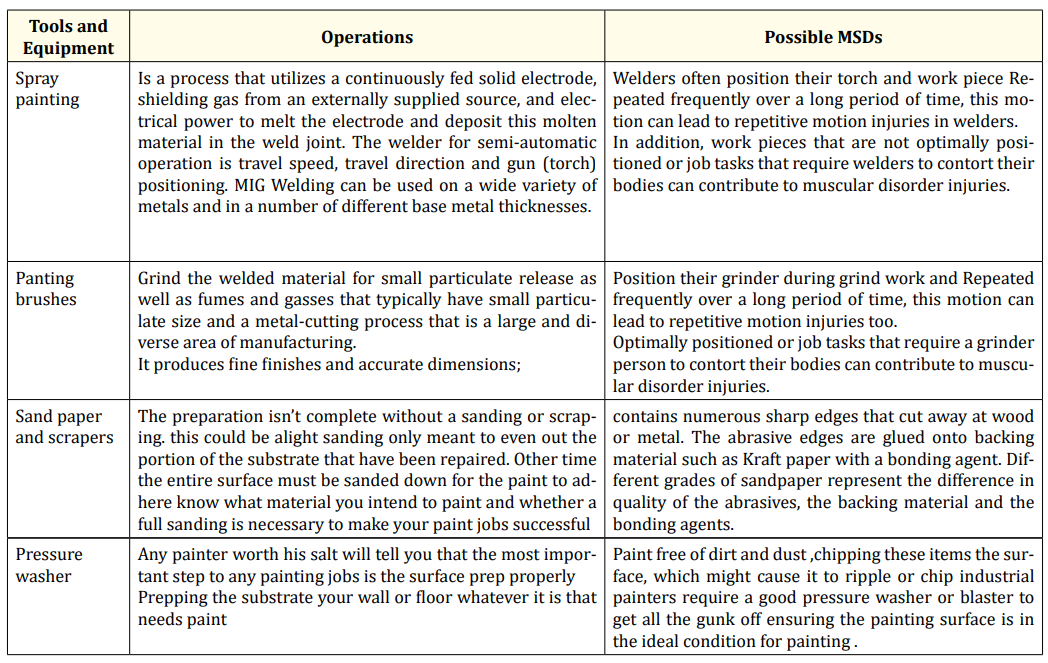

Table 1: Literature review summery.

This data are collected based on medical record and ways doings at Akaki kaliti Basic Metal Industry workers. It is collected to assess the effects of work related musculoskeletal disorders. To evaluate this different data are collected from different perspectives by interviews and observations.

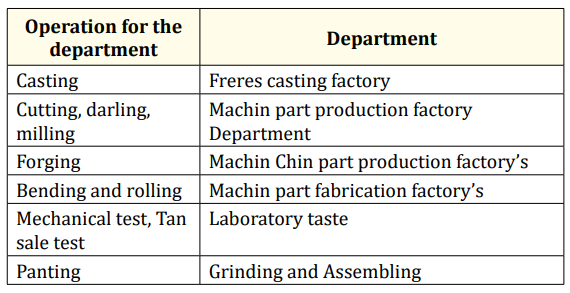

There are four main production rooms in the factory. Their corresponding operations are stated as follows. There are four main production rooms in the factory. Their corresponding operations are stated as follows.

Standard product and engineering production room: In this production room there are different types of operations to accomplish the factory's overall production achievement. Some of them are

Table a

Other production room are Machin part fabrication factory

From the above production room most of the welding production process is in the production of track and trailer and we can find medical records b/c of muscular disorder from medical recorded data of the company.

Table b

From the above table we can understand muscular disorder problem is one of the major risen but it has less medical recurred rather than the others b/c effects of muscular disorder are seen mostly when the age of the person increase but for this study purpose we try to divide muscular disorder problem in production room.

Table 2: Medical records.

Picher 1: Working in front and Working above the shoulders at standing position. Most injures caused by this position is hand muscle disorder during holding the painting material.

Figure 1

Picher 2: Working at ground level at different work shop during painting.

Picher 3: Panting and spry painting under the work piece working cycle is basically slight bending for positioning the welding. From the observation when axel is produced painting under the axel is necessary like shown in the figure it has been noted that this working position is one of the risky tasks.

Figure 2

Figure 3

Picher 4: Is the reaching and forward bending pose common in the gear box housing and spry painting trade. Painter often grabs painting guns and target to hit inclined work pieces by bending and reaching their back. This posture is mostly repetitive in daily routines.

Picher 5: Portrays the common kneeling position of a painter. This posture is required in certain painting circumstances when are large and complex or difficult to lift up. This position is very common in most of the painting works. The painters may rely on knee support on the floor and yet the back and neck are in awkward positions. Also extended durations or repetitions might add additional MSD risks to knee and joints as well

Picher 6: Working at ground level at different work shop during painting

Figure 4: Spray painting and painting in different position.

Table 3: Evaluation of Musculoskeletal Disorder Hazards.

Musculoskeletal disorders in welding tasks at Akaki kaliti Basic Metal Industry are serious concerns. Ergonomic risk evaluation of panting tasks is crucial as these have strong connectivity with PMSDs. As it observed from study; Poor workstation design and layout; Lack of awareness of ergonomic principles and standard Long exposure of work and Lack of skilled operator are the responsible factors for the cause of WMSDs in Akaki Basic Metal Industry painting area worker.

Copyright: © 2020 Kassu Jilcha and Helina Assefa. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

ff

© 2024 Acta Scientific, All rights reserved.