Wafaa M Salama*, Atiat S Dosuky and Esmat Aly

Dairy Research Department, Food Technology Research Institute, Agricultural Research Center, Giza, Egypt

*Corresponding Author: Wafaa M Salama, Dairy Research Department, Food Technology Research Institute, Agricultural Research Center, Giza, Egypt.

Received: September 12, 2024; Published: September 26, 2024

Citation: Wafaa M Salama., et al. “Increasing the Added Value of Potato Peels by Producing Processed Cheese with High Nutritional Value". Acta Scientific Nutritional Health 8.10 (2024):49-57.

The present study was conducted to investigate the effect of partially incorporating potato peel powder (PPP) in the formula of processed cheese on the physicochemical, textural and sensory properties of the final product. PPP was used to substitute 1, 2, and 4% of the fresh soft cheese curd in a processed cheese blend. The resultant processed cheese samples were stored for 90 days at 5±2ºC.The results found that incorporation of PPP in processed cheese increased the protein and ash contents and acidity values but decreased moisture, meltability, and oil separation of the resultant cheese. All texture parameters (hardness, springiness, gumminess, cohesiveness, and chewiness) except adhesiveness, increased with the increased amount of PPP. Also, higher total phenols content (TPC) and antioxidant activity (AOA) values have been obtained by increasing the added amount of PPP and also with the progression of the storage period. The best sensory evaluation was found with control samples followed by processed cheese samples containing 1 and 2% PPP, while the lowest sensory degrees were observed with 4% PPP. According to this study, PPP may be added to processed cheese at a ratio of 1 and 2% as an inexpensive, healthy, and useful component.

Keywords: Processed Cheese; Potato Peel Powder; Texture Profile; Antioxidants And Sensory Properties

It is well-known that the food industry leads to the accumulation of a huge amount of waste and byproducts. The disposal of these agro-food wastes in an improper manner leads to environmental contamination. Additionally, many important nutrients such as antioxidants, some minerals, vitamins, etc are lost in these wastes. For this reason, the exploitation of these wastes achieves the concept of sustainable development, protects the environment, and opens a new approach to obtain a lot of additives of great value, which might be added to improve the physicochemical, sensory, and functional properties of food.

Potato peels (PP), generated from the potato industry, is an inexpensive agro-industrial waste and contains a large quantity of starch, non-starch polysaccharides, and lignin. Moreover, it is considered an excellent source of several bioactive compounds including fibers, minerals, and polyphenols. For this reason, it is not only considered a cheap source but also a valuable base material for the extraction of beneficial components such as natural antioxidants, dietary fiber…etc [1]. Therefore, it is well-known for its strong bioactive properties and its role in prolonging the shelf-life of food products [2,3]. Previously, PP has been exploited as a part of fermentation media, in synthesizing numerous compounds such as lactic acid, ethanol, acetic acid, biohydrogen, enzymes, biogas, and biofertilizers [4].

Processed cheese is among the most popular dairy products that are commonly consumed among different age categories. It is produced by mixing natural cheeses of various degrees of maturity in the presence of emulsifying salts under heating and normal pressure or partial vacuum until a homogeneous mass is obtained [5]. Several ingredients can be used in manufacturing processed cheese including dairy and non-dairy products such as vegetables, fruits, and spices [6]. Also, many by-products and food processing residues, which are of high nutritional and functional values, might be used, which reflects in turn on the nutritional value of the resultant processed cheese. Subsequently, there is a great variety of these commercially marketed cheeses in terms of taste, color, and composition, which reflects on their increased acceptance and thus an increase in their economic return. Previous studies reported that the fortifying processed cheese with natural bioactive ingredients has increased significantly in the past few years, for example, the incorporation of soy bean flour [7], chickpea flour [8], maize germ cake [9] and wheat germ powder [10] into cheeses, which resulted in improved nutritional value and organoleptic properties, and extended the shelf life of cheese types. To our knowledge, there is no existing literature on using PPP as a food raw material in processed cheese manufacturing. Therefore, the main objective of the present study was to investigate the effects of potato peel powder (PPP) on the physicochemical, textural, and sensory characteristics as well as nutritional value of processed cheese.

The Ras cheese, 3 months old and unsalted butter were purchased from a local market in Giza, Egypt. Fresh Soft cheese curd was manufactured usingfresh skim buffalo milk obtained from the Faculty of Agriculture, Cairo University, Egypt. Cooking salt (Joha S9s emulsifying salt special) was obtained from BK Ladenburg Corp., Gmbh, Germany.2,2-diphenyl-1-picrylhydrazyl (DPPH) was obtained from Sigma-Aldrich (Steinheim, Germany) while gallic acid monohydrate and Folin-Ciocalteu reagent were obtained from Fluka (Madrid, Spain). All reagents used were of analytical grade.

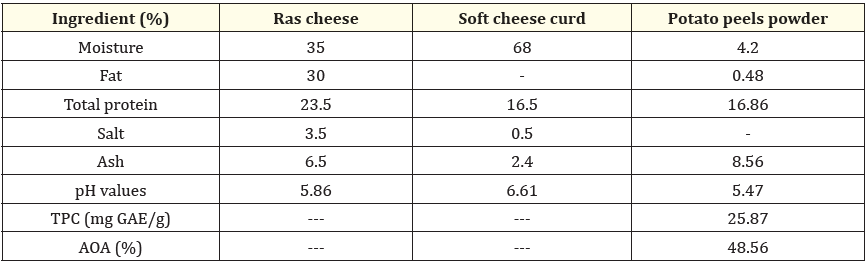

Potato tubers were washed with water and peeled carefully using a knife. The whole potato peels were air dried in a ventilated oven at 40˚C for 48 h, ground to a fine powder then sieved (60mesh). The obtained fine powder was packaged in polyethylene bags and kept refrigerated and used during 30 days in the experiments. The composition of potato peel powder is as shown in table 1.

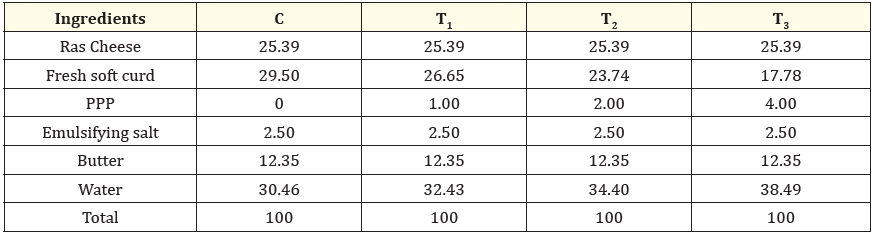

The various formulations of processed cheese were manufactured according to [11]. Fresh soft cheese curd, Ras cheese, butter, water, and emulsifying salt with/or without adding potato peel powder have been used in manufacturing the processed cheese samples. Generally, the different blends were formulated to contain 60% moisture, 40% fat per dry matter, and 2.5% emulsifying salts (Table 2 shows the formulations of processed cheese samples). Control samples and other treatments have been formulated with added 0, 1, 2, and 4% of PPP and named C, T1, T2, and T3, respectively.

All ingredients of each blend were placed and well-mixed in a double jacket pan (batch capacity of 2 kg at a stirring velocity of 120 – 140 rpm). The obtained mix of the blend has been cooked at 85 ± 2oC using indirect steam for 10 min at a pressure of 2-2.5 kg/cm2. After that, the resultant processed cheese was promptly hot-filled into appropriate glass receptacles, sealed, kept at 5°C for 90 days, and subjected to analysis at intervals of 3 months. The chemical compositions of Ras cheese, soft cheese curd, and PPP used in formulating spreadable processed cheese are shown in table 1.

Three replicates were carried out for each processed cheese treatment. The prepared samples underwent the following analyses

The proximate analyses including moisture, protein, fat, ash, pH, and acidity have been determined according to [12]. Specific factors of 6.25 and 6.38 have been used to calculate the total protein content in PPP, and dairy materials, respectively. Soluble nitrogen content was estimated as described by [12]. Meltability and oil separation were estimated according to [13], and [14] respectively. Texture parameters were measured at 23°С as described by [15] using an Instron Universal Testing Machine model 1195, Stable Micro System (SMS) Ltd., Godalming, UK, loaded with Dimension Software SMS program.

For extracting the phenolic compounds, the processed cheese (2g) was mixed with an aqueous methanolic solution (30 ml, 70:30 v/v) with stirring for 24 h at ambient temperature protected from the light to avoid polyphenols degradation by photo-oxidation. After centrifugation for 20 min at 4000 g, the supernatant was collected and the residue was re-extracted with an additional 30 ml of the same solution and recombined together. The obtained supernatant has been utilized in the estimation of TPC, and AOA.

Total phenols content (TPC) has been estimated according to [16] and the results were expressed as mg GAE/g. The antioxidant activity (AOA) has been estimated using DPPH as radical scavenging activity of methanolic extracts according to [17].

Processed cheese samples were subjected to sensory evaluation according to [18]. Ten expert panelists belonging to Dairy Research Dept., Food Technology Research Institute, Giza, Egypt were recruited to conduct the sensory evaluation using the following descriptors: color (20 points), texture (40 points), flavor (40 points), and overall acceptability (100 points).

All data (mean of three replicates) were analyzed by the General Linear Models of [19]. Means were compared by Duncan’s test at the significance level of P ≤ 0.05.

Although agro-industrial wastes are cheap sources, they are well-known for containing several beneficial ingredients that recently received more attention to be exploited as food additives for improving the physicochemical and functional properties of foods. Among these wastes, potato peels recently gained more attention as they represent an excellent source of several nutrients including protein, fiber, and polyphenols among others. The findings presented in Table1 revealed that PPP had a higher amount of total protein of 16.86%, lower moisture content of 4.2%, and lower fat content of 0.48%. The ash content of potato peel powder is accounting for 8.56%. The pH value of this powder was 5.47. These findings are in general agreement with those reported by [20] who found a similar proximate composition for potato peel powder with slightly lower values. Also, similar results have been obtained by [21-23]. Also, table 1 displayed the chemical composition of Ras cheese and fresh soft cheese curd used in preparing the processed cheese. Ras cheese had 35% moisture, 30% fat, 23.5% protein, 3.5% salt, and 6.5% ash, and also had a pH value of 5.86. The current results exhibited that soft-cured cheese had 68% moisture, 16.5% protein, 0.5% salt, 2.4% ash, and a pH value of 6.61. Awad., et al. [24] used the same raw material (Ras cheese and soft curd cheese) in preparing the processed cheese but they reported relatively higher values of these parameters, except ash content. This could be due to the variation in raw material's age, and composition.

Table 1: Chemical composition (%) of potato peel powder, Ras cheese and soft cheese curd used in formulating the processed cheese.

Values are means of three independent replicates. TPC: Total Phenolic Content, GAE: Gallic Acid Equivalent, AOA: Antioxidant Activity.

Table 2: Composition of different blends of processed cheese made using potato peels powder (Kg/100Kg). C, T1, T2, T3: Processed cheese samples supplemented with 0, 1, 2 and 4% potato peel powder

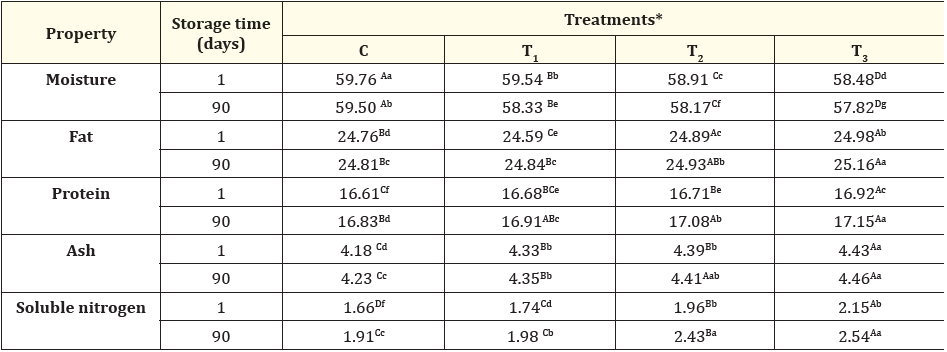

Table 3 displayed the chemical composition of the formulated processed cheese samples with/without PPP. The current results confirmed that various formulated processed cheese samples have proximate compositions very close to the proposed composition adjusted during the formulation of their blends. By the end of storage, a lower moisture % was found in the T3 (4%PPP) samples, while the control samples had the highest moisture %.These results are in line with the finding of [9]. The current results showed an increase in total protein, soluble nitrogen, and ash contents by increasing the added amount of PPP. This increment in total protein, soluble nitrogen, and ash contents in processed cheese treatments with added PPP as a substitution for raw cheese is related to the higher values of protein and ash in PPP compared to soft curd used in the base formula in table 1. Similar results have been reported by [24,25] who reported an increment in protein and ash contents by adding lupin paste or date seed powder, respectively. Significant changes were found in the protein, soluble nitrogen and ash values of all samples during cold storage. Similar results were reported by [9]. Also, the findings in Table 3 revealed that the contents of fat, protein, and ash slightly increased with the progress of cold storage. So, these values were higher at 90 days of cold storage, compared to the first day. Also, during storage, soluble nitrogen values increased with the progress of the cold storage period in all treatments including the control sample. The enzymatic activity of product-resistant proteinase represents the main contributor to the observed changes in soluble nitrogen. Another explanation is the breakdown of emulsifying salts, polyphosphate in particular, leading to higher protein solubilization. Awad., et al. [24] obtained similar findings. Generally, after 90 days of cold storage, T3 had the lowest moisture content and the highest contents of ash, fat, protein, and soluble nitrogen, compared to the control sample and T1, and T2.

Table 3: Chemical composition (%) of processed cheese containing different levels of potato peel powder when fresh and during storage at refrigerator (5 ± 1ºC).

*C, T1, T2, T3: processed cheese samples supplemented with 0, 1, 2 and 4% potato peel powder.

A, B, C: Means with the same letter among treatments are not significantly different (P ≤ 0.05).

a, b, c: Means with the same letter during storage period are not significantly different (P ≤ 0.05).

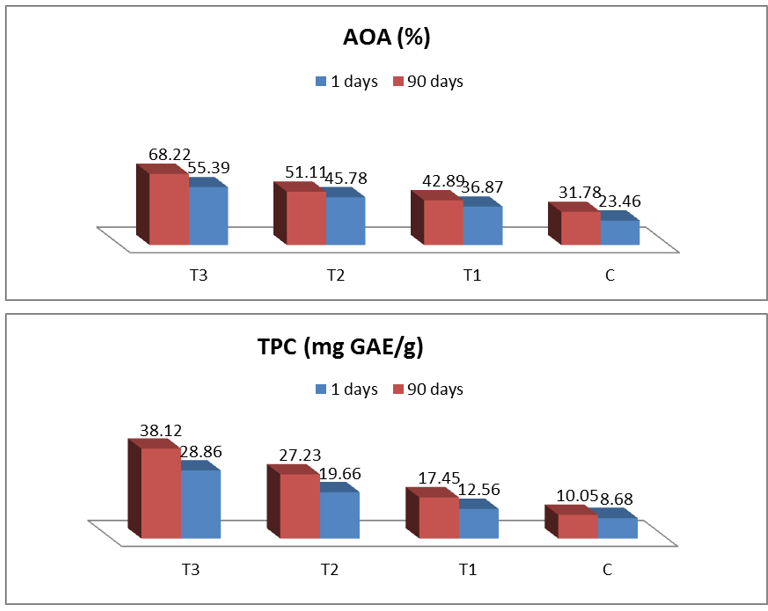

The functional properties of processed cheese are affected by various factors, such as the type and properties of natural cheese, supplemental ingredients, emulsifying conditions, moisture, pH, fat content, cooling, and ripening [26]. The results in figure 1 showed the effect of adding PPP on the TPC and AOA values of processed cheese at 1 and 90 days of cold storage period. The results indicated that fresh control cheese had the lowest value of TPC, accounting for 8.68 mg GAE/g. TPC values (ranging from 12.56 to 28.86 mg GAE/g) significantly increased with the increased amount of PPP added to processed cheese. This probably be due to that PPs are described as being a rich source of phenolic compounds, which have been related to human health benefits [27]. In the same context, the content of phenolic compounds in PP is up to ten times higher than in potato flesh [2,28]. At the end of cold storage, TPC content significantly increased in all cheese samples including control to reach 10.05 - 38.12 mg GAE/g. This increase may be due to the lower moisture content in these cheeses. Additionally, the breakdown that occurs in the phenolic compounds during storage might increase the total phenolic content which could result in the conversion of polymeric polyphenols to monomeric ones. The increase in TPC values positively reflects in turn on increasing the antioxidant activity of the cheese samples. Consequently, a similar tendency has been obtained for AOA values where higher AOA values have been recorded by increasing the added amount of PPP and also with the progress of the storage period. In most studies, a significant positive correlation was also found between the antioxidant activity and the phenolic content of PP extracts [2,29].

Figure 1: Antioxidant activity (AOA) and Total phenols content (TPC) of processed cheese containing different levels of potato peel powder when fresh and during storage at refrigerator (5 ± 1ºC).

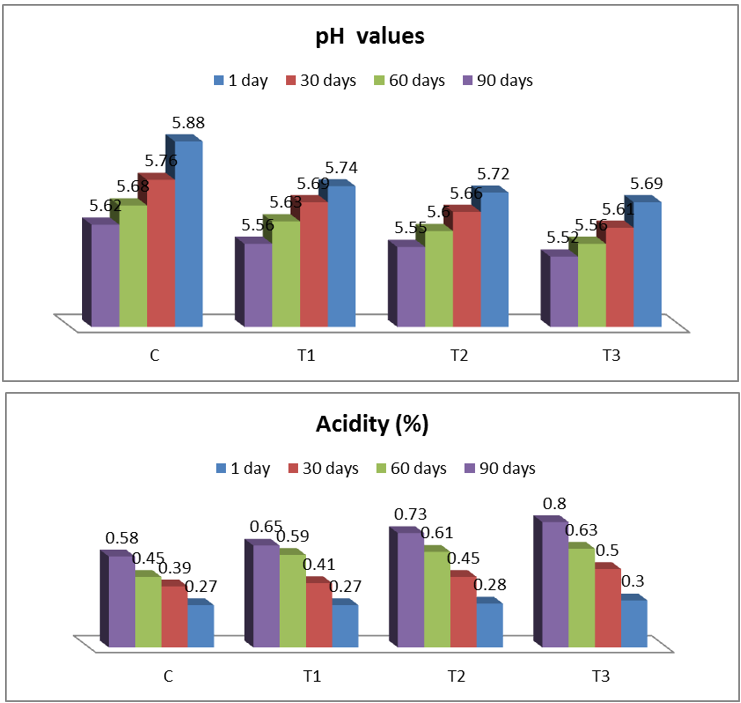

The data displayed in figure 2 showed the pH and acidity values of processed cheese samples during 90 days of cold storage. The data revealed that changes in pH and acidity values were time-dependent and composition-dependent. Generally, PPP incorporation led to lowering pH values. Thus, the lowest pH value (5.69) was recorded for the processed cheese sample with 4 % PPP (T3), compared with the highest value (5.88) which was recorded for the control cheese sample. This could be mainly due to the lower pH value (5.47) of PPP compared to 5.86 and 6.61 for Ras and soft cheese curd, respectively. pH values of all samples gradually decreased during the cold storage period for 90 days. The observed pH decline during storage time is mainly attributed to the breakdown of emulsifying salt and its interaction with proteins. The changes in pH values were almost insignificant. Several authors reported similar findings regarding pH changes in processed cheese during storage time [9,30], attributing these changes to a similar explanation. The opposite tendency has been obtained for acidity values where higher acidity values by increasing the added amount of PPP. Awad., et al. [24]. recorded a similar trend in acidity by adding lupin paste.

Figure 2: pH values and Acidity (%) of processed cheese containing different levels of potato peel powder when fresh and during storage at refrigerator (5 ± 1ºC).

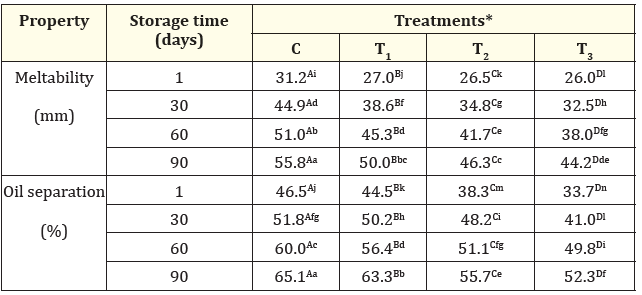

The effect of PPP as a new additive on the meltability of processed cheese is presented in table 4. The data indicated that the control cheese had the highest meltability value. The addition of PPP has decreased to a certain extent the meltability of resultant processed cheese. All treatments with PPP had significantly lower meltability values than the processed control. Accordingly, the control sample has the highest meltability value followed by the containing (T1). The lower meltability values in treatments with PPP could be due to the lower moisture content in these cheese samples (Table 3). The addition of PPP (a rich source of fiber) in treated cheese samples increased the water-holding capacity, which led to a lack of free water [31]. All samples exhibited an increase in meltability values (significant at P ≤ 0.05) of processed cheese including control treatment after 3 months of storage at 5 ± 2˚C. The increase in meltability values of stored samples could be related to the hydrolysis and protein breakdown that occurred in the cheese matrix, which leads to high soluble nitrogen content and an increase of cheese flow in agreement with the findings reported by [32]. The changes in oil separation values of all treatments, whether fresh or stored, had a similar trend to that of meltability in agreement with that reported by [31].

Table 4: Meltability (mm) and Oil separation (%) of processed cheese containing different levels of potato peel powder

when fresh and during storage at refrigerator (5 ± 1ºC).

A, B, C: Means with the same letter among treatments are not significantly different (P ≤ 0.05).

a, b, c: Means with the same letter during storage period are not significantly different (P ≤ 0.05).

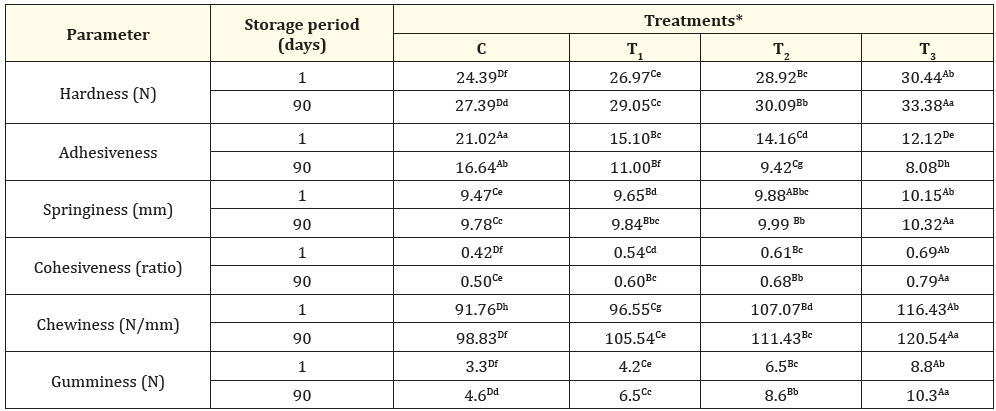

Table 5 illustrated the texture parameters of processed cheese samples containing 0, 1, 2, and 4 % of PPP at 1, and 90 days of cold storage time. All texture parameters, except adhesiveness, increased with the increased amount of PPP. In this sense, adding 4% of PPP (T3) led to the highest values of hardness, springiness, gumminess, cohesiveness, and chewiness, and the lowest value of adhesiveness, as compared to the control sample. Texture parameter values have been proportionally changed by adding PPP. Additionally, the progress of cold storage time led to an increasein all texture parameters except adhesiveness. Unlike the control sample, the processed cheese sample containing 4% PPP (T3) at 90 days of storage, had the lowest value of adhesiveness (8.08) and the highest values of hardness (33.38 N), springiness (10.32mm), gumminess (10.3N), cohesiveness (0.79), and chewiness (120.54 N/mm).Generally, significant changes have been recorded (P ˂ 0.05) in all texture parameters by incorporation of PPP, and progress of cold storage time. The changes that occurred in texture parameters could be due to the difference in formulation of each processed sample. In this context, casein represents the main protein in the control sample while PPP-containing samples had different concentrations of protein derived from potato peel powder along with the casein protein. Based on this, it is proposed that variation in texture parameters could mainly be attributed to the variation in the occurring protein types and concentrations present in processed cheese samples [33]. Similar findings of texture parameters have been reported by adding rice bran [34], and date seed powder [25] to processed cheese. This observation has been ascribed to the less water availability and reduction in moisture content during storage time, and hence the increased viscosity in treatment samples [35]. Similarly, increased values of hardness have been obtained by [30,36] at the final storage time of processed cheese samples. Excepting the adhesiveness, an increment was observed in the values of springiness and cohesiveness, gumminess, and chewiness by increasing the added amount of PPP and the progress of cold storage time. Similar previously reported findings were observed by [24].

Table 5: Texture profile analysis (TPA) of processed cheese containing different levels of potato peel powder when fresh

and during storage at refrigerator (5 ± 1ºC).

A, B, C: Means with the same letter among treatments are not significantly different (P ≤ 0.05).

a, b, c: Means with the same letter during storage period are not significantly different (P ≤ 0.05).

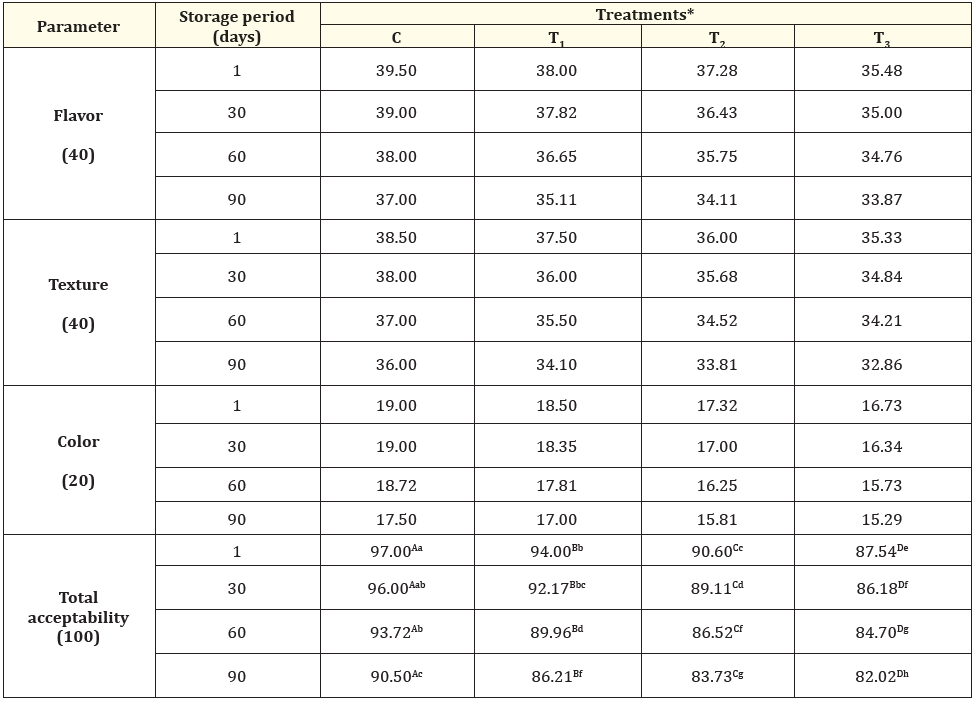

Recently, Food products containing naturally occurring components that are beneficial to health, such as enzymes, antioxidants, probiotics and prebiotics, natural extracts, antimicrobials, and essential oils derived from plants, have demonstrated a preference among consumers [37]. Sensory evaluation is an important indicator of potential consumer preferences. Sensory evaluation of processed cheese with PPP is shown in table (6). From the obtained results, it is obvious that cheese control gained the highest score while the lowest score was gained by T3 (4%PPP). Among treatments, there were no major changes in cheese flavor and texture. All treatment samples were sensory acceptable and the treatment containing 1% PPP was the most acceptable sample. Fresh-treated cheeses exhibited nearly both flavor and texture values but the color highly differed from one treatment to another. The addition of PPP into the blend led to a light brown color of resultant cheese and the light brown color became more obvious with increasing the added amount of PPP. Generally, the color of the final product is affected by the ingredients used in the manufacture of cheese. The data showed significant changes between the control sample and cheese supplemented with 4% of PPP. From the data shown in Table (6), the sensory quality of all samples gradually decreased during the storage period reaching the lowest score after 3 months. The decrease in the organoleptic properties during the storage period is attributed to the changes that occurred in the functional properties of cheese. These results are in line with the findings of [31].

Table 6: Sensory properties of processed cheese containing different levels of potato peel powder when fresh and

during storage at refrigerator (5 ± 1ºC).

A, B, C: Means with the same letter among treatments are not significantly different (P ≤ 0.05).

a, b, c: Means with the same letter during storage period are not significantly different (P ≤ 0.05).

This study investigated the effect of using potato peel powder (PPP) on the physicochemical, textural and organoleptic properties of processed cheese. The addition of PPP caused an increase in protein content, TPC and AOA values of processed cheese. Cheese control gained the highest score while the lowest score was gained by T3 (4%PPP). During storage, the control and PPP 1% samples (T1) showed higher acceptability values compared to all other treatments followed by the PPP 2% samples (T2) then PPP 4% samples (T3). Therefore, this study recommends the use of PPP as a low-cost nutritional and functional ingredient up to 2% in the preparation of processed cheese.

Copyright: © 2024 Wafaa M Salama.,et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.