Dupe Temilade Otolowo1*, Ayomide Elizabeth Atoyebi1, Oluwamuyiwa Adekanmi Babarinsa1, Gbenga David Ayandiran1, Modupe Deborah Amidu1 and Oluwatooyin Faramade Oludahunsi2

1Department of Food Science and Technology, Mountain Top University, Nigeria

2Department of Food Science and Technology, Federal University of Technology, Akure, Nigeria

*Corresponding Author: Dupe Temilade Otolowo, Department of Food Science and Technology, Mountain Top University, Nigeria.

Received: June 04, 2024; Published: August 29, 2024

Citation: Dupe Temilade Otolowo., et al. “Nutritional Improvement and Potential Health Implication of Fortifying Fast Foods with Citrus Fruit Wastes Dietary Fibre". Acta Scientific Nutritional Health 8.9 (2024): 72-81.

Fast foods are characterised by low dietary fibre and habitual consumption has been linked to non-communicable diseases. Citrus fruit residues usually discarded as wastes after processing could find useful applications in food systems, especially as sources of dietary fibre. Hence, citrus fruit waste dietary fibre (CFWDF) powders were produced from mixtures of dried segment walls (A) and pith/albedo (B) of four selected citrus fruits and were evaluated for physicochemical, functional properties, and soluble and insoluble dietary fibre constituents. Cake and doughnuts fortified with 15% CFWDF were evaluated for nutritional, colour, and sensory properties and the unfortified products served as control. The results showed that the CFWDF powders (A and B) had a low range of titratable acidity (0.12 to 0.47g/100g) which could imply low-acid-fortified products which is desirable especially for ulcer patients. Low ranges of moisture content (8.29 to 8.93g/100g) and water activity (0.55 to 0.57) of CFWDFs indicate stability against microbial proliferation and the consequent ease of handling during the application in the food system. The CFWDFs also exhibited good functional properties that supported quality dough formation during the production of cake and doughnuts. The soluble and insoluble dietary fibre ratio in CFWDF powders (A and B) met the standard ratio of 1:2 respectively implying their suitability for food application. However, CFWDF–B was unsuitable for fast food fortification as it imparted a bitter taste to the products and was discontinued in the fortification treatment. Thus, CFWDF–A fortified fast food had lower moisture contents (20.66%cake and 19.62%doughnut) which could mean a longer shelf life than the corresponding unfortified (control) products (23.47 and 20.93%, respectively). The crude fibre of the fortified products was significantly (p < 0.05) improved (0.66%cake and 1.04%doughnut) as well as the ash for doughnut; indicating nutritional improvement and consequent potential health implications of the CFWDF fortified products. The entire products had all the determined sensory attributes preferred within the panelists’ ratings of 7 and 8 (approximately) on the 9-point hedonic scale with a high overall acceptability rating range of (7.5 to 8.3) and no significant difference in that of the fortified and control cake. This showed that the products were acceptable to panelists. The nutritional improvement in fortified products could alleviate the health risk factor of frequent consumption of fast foods without changing habits.

Keywords: Citrus Fruit Wastes Dietary Fibre; Fast Food Fortification; Nutritional Properties; Colour Evaluation; Sensory Properties

CFWDF: Citrus Fruit Wastes Dietary Fibre; A: Mixture of Segment Wall of Citrus Fruit Wastes; B: Mixture of Pith (Albedo- Whitish Spongy Part) of Citrus Fruit Wastes; SDF: Soluble Dietary Fibre; IDF: Insoluble Dietary Fibre; ZF: Cake Fortified with Citrus Fruit Wastes Dietary Fibre; ZN: Cake with no Citrus Fruit Wastes Dietary Fibre; YF: Doughnut Fortified with Citrus Fruit Wastes Dietary Fibre; YN: Doughnut with no Citrus Fruit Wastes Dietary Fibre; TDF: Total Dietary Fibre; TTA: Titratable Acidity; W: Commercial Wheat Flour; nd: Not Detected; na: Not Applicable; WAC: Water Absorption Capacity; OAC: Oil absorption Capacity; LBD: Loose Bulk Density; PBD: Packed Bulk Density; L: Lightness Axis; a: Red-Green Axis; b: Yellow-Blue Axis

Citrus fruits are popular fruits widely consumed throughout the world as fresh produce with one-third of the crop being processed into juice, and some other products, resulting in the generation of approximately 50-60% wastes including peels, seeds, and membrane residues [1-3]. These residues, typically discarded and viewed as wastes are rich in fibre that could find a potential application as a fortification agent to be explored in food systems [3]. Particularly, due to the large volume generated and ease of access, citrus wastes can provide dietary nutritional supplements that may be a significant source of dietary fibre [4] to improve the nutritional and health benefits of foods that lack or are low in dietary fibre such as fast foods [5]. Moreover, refined wheat flour is the principal ingredient in the production of most fast foods, especially pastries (such as cakes, meat pies, doughnuts, chin-chin, hamburgers, egg rolls, buns, puff-puff, fish rolls, samosas, biscuits, cookies, etc). It is also added as a binder or adjunct in other fast foods like sausages. However, wheat flour loses its dietary fibre constituent (the bran) to the milling process [6] and this necessitates the fortification of fast foods with dietary fibre from other sources.

Fast foods sometimes called junk foods are low in dietary fibre, but high in saturated fat, salt, and sugar content [7], however, they are assumed to be inexpensive, convenient, easily accessible, and tasty [8,9]. Moreover, despite having no balanced nutrients, fast foods have been among the most popular foods by humans and command a high level of consumption in global societies. These might have resulted from their versatility in satiating appetite [10,11]. Thus, dietary fibre-fortified products will reach a large population of consumers with potential health benefits. Additionally, frequent consumption of fast foods is documented as the major cause of nutritional disorders and non-communicable diseases prevalent in our world today [12,13]. Clinical studies have demonstrated that some constituents of fast foods are associated with health consequences such as obesity, and eating disorders, as well as chronic diseases such as cardiovascular diseases, high blood pressure/hypertension, cancer, and Type 2 diabetes [14,15]. Testing on rats revealed that fast food has negative effects that may manifest similarly in humans. A study published in the British Journal of Nutrition as noted by Surya (2020) [16], discovered that pregnant female rats who ate fast food increased the likelihood of their offspring developing unhealthy eating habits. Also, other research on the impact of sugary foods on human emotional health has found that eating fast food can hurt energy levels and emotional well-being [16]. Consequently, the consumption of fast foods has raised concerns among the health-conscious and risk-prone population [13].

Nevertheless, irrespective of the advocacy for healthy eating habits, the change in habits consumption of fast foods seems insignificant [17]. Research findings have shown that 37% of adults in America's population consume fast foods with a portion of this population being addicted to it. This causes a high rate of disorders in human health [15]. Also, more than 33% of adults and 17% of children and teenagers are obese in the United States which might not be unconnected with the frequent consumption of fast foods [18,19]. In Nigeria, over 75% of university students (42.9% males and 32.9% females) patronise and consume fast foods and more and more Nigerians are getting addicted to the fast food syndrome especially university undergraduates [20,21]. This implies that many advocacies on cutting down on high consumption of sugar and fats (characteristics of fast foods) by WHO and other interventions recorded minor successes as per change in the habit [22,23]. Therefore, an alternative remedy is fortifying fast foods with dietary fibre though, may not stop addicted consumers from eating but will support their health by improving digestion and helping to prevent the associated health disorders emanating from lack or low fibre diets.

Food fortification is adding one or more deficient nutrient(s) to commonly consumed foods. It is documented to be a proven and cost-effective intervention for addressing deficiencies by improving the nutritional quality of the food supply in the population [7,24]. When implemented under necessary conditions and sustainably, fortification is an effective and low-cost intervention to address nutrient deficiencies. It is also said to be an “opportunistic” intervention because it takes advantage of an existing product and its delivery system without any requirement for behavioural or habit change [7]. Therefore, finding a useful application for citrus wastes as potential dietary fibre ingredients in food fortification implies value addition and could contribute to environmental protection from poor waste management [6]. In addition, it is undeniable that exploring the combined effect of citrus wastes as sources of dietary fibre in cake and doughnut fortification is scarce in the literature. Also, considering the versatility and universality status of cake and doughnuts, research of this sort could not be overemphasised.

Dietary fibres are found in plants (fruits, vegetables, and cereal grains). They are essential in any heart-healthy diet and have been connected to several other health benefits [25,23]. The soluble dietary fibre in food is known for the absorption of glucose in the human system and the consequent reduction of postprandial blood glucose and the risk of diabetes mellitus [26]; the insoluble portion helps in bowel movement and maintenance of gut health [27]. Consequently, a rich fibre diet can decrease the risk of metabolic disorder which is a risk factor associated with diabetes, coronary heart disease, and stroke [28,29]. Thus, adequate dietary fibre in human diets generally enhances well-being as reported by [6]. The average daily requirement of dietary fibre is 21–25g per day for women and 30–38g per day for men [1,5]. Therefore, even though the rate of change in consumption habits is slow, fortifying fast foods to raise the dietary fibre content could help to meet the daily requirement and solve the problem of human health disorders associated with low-fibre diets. Thereby, establishing a useful application for citrus wastes in the food system which in turn, could lead to some improvement in the cultivation of citrus fruits.

Thus, the major aim of the present work is to evaluate the quality properties of dietary fibres derived from a mixture of citrus fruits’ segment walls and pith (albedo) and the nutritional improvement of the fortified cake and doughnut.

For this research, four different species of citrus fruits; orange (Citrus X sinensis), white grapefruits, red grapefruits (Citrus X paradisi), and lemon (Citrus limon) were purchased from Ketu market, Lagos, Nigeria while the ingredients used for the preparation of fast foods; wheat flour, sugar, margarine, eggs, baking powder, vanilla essence, nutmeg powder, instant baker’s yeasts, and vegetable oil were purchased from Ibafo market, Ogun State, Nigeria. The chemicals used for the analysis were of analytical grade.

The method described by [6] with modifications of no soaking and different drying temperatures was adopted to produce the citrus fruit waste dietary fibre (CFWDF) powders. The fruits; orange, white, and red grapefruits, and lemon, chosen based on literature recommendation [30], were thoroughly washed to remove dirt and adherent extraneous materials before being peeled manually with a sharp kitchen knife. The pith/albedo (the white spongy part) was separated from the pulp and cut into smaller pieces to ease the drying operation. A kitchen juice extractor (MILKACHI, Model: MK-1706, CHINA) was used to extract the juice from the pulp. The residues, mainly of the segment walls (that housed the juice sacs) were sieved with a muslin cloth to remove excess juice and the seeds were removed. The segment walls coded as (A) and pith (B) were thinly spread on separate trays and sun-dried to reduce the wetness before being dried to a constant weight in an air draught oven at 60℃ for 3-4 hours. Obtained dried wastes were cooled and milled in a laboratory hammer mill (Model: 3100-v3.4 EN, SWEDEN) with a sieve aperture of 0.8 mm to obtain uniform-size fibre powders employed as the dietary fibre ingredients.

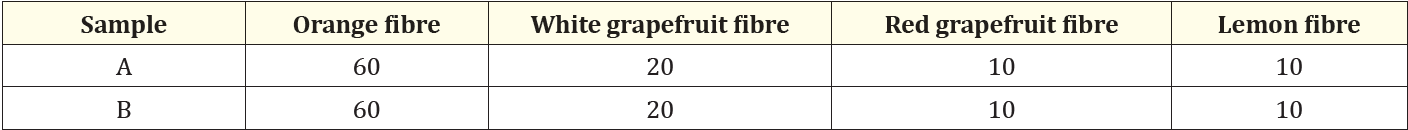

The Optimal design of the mixture response surface methodology (MRSM) was used to formulate the ratio of the citrus waste fibre from each fruit to determine the proportion of orange fibre, white grapefruit fibre, red grapefruit fibre, and lemon fibre in each mixture of the dietary fibre powder. The combined ratios of the fruit waste fibre were separately built by imputing a similar range of values in the MRSM for each fruit in the segment walls (A) and pith (B). These ranges were chosen based on the relative abundance of each fruit during the season according to the literature [31] recommendation. Only one MRSM run in each case appeared in whole number figures and were the same in magnitudes for both segment walls and pith. These combined ratios were randomly selected for ease of measurement during the experiment as depicted in table 1. Fibre mixtures were packaged in separate air-tight containers pending the uses.

Table 1: Formulation (%) for the citrus wastes’ fibre powder mix. A = Mixture of segment wall of the citrus wastes; B = Mixture of pith/albedo (the white spongy part) of the citrus wastes.

The pH and titratable acidity (TTA) were determined by the methods described by [33]. Moisture content was determined using the moisture analyzer (model MB45 OHAUS made in Switzerland). The equilibrium relative humidity (ERH) was measured using a manual Temperature Clock/Humidity meter (TOWAYER, Model HTC-2) at ambient temperature (26-28oC). The sensor is buried in the sample in a closed container, and the reading on the meter was left to reach equilibrium when the reading became relatively constant and was recorded as the equivalent water activity (aw) by dividing the obtained value by 100.

The procedure of [34] was followed in determining the water and oil absorption capacity. One (1) gram of the sample was weighed into a clean centrifuge tube and thoroughly mixed with 10 ml of distilled water or oil for 30 seconds using a stirring rod. The sample was allowed to stand at room temperature for 30 minutes before being centrifuged at 3500 rpm for 30 minutes. The volume of the supernatant for water and oil absorption was read from the graduated centrifuge tube after centrifugation. By multiplying the density of oil (0.894 g/mL) and water (1g /mL), the absorbed water was converted to weight (in grams). The oil and water absorption capacities were expressed in grams of oil and water absorbed per gram dry weight of the sample (g/g dw).

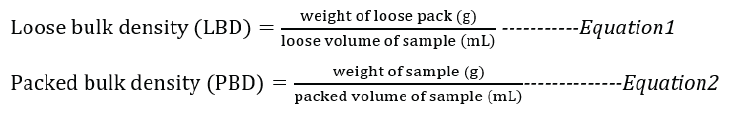

The method described by [35] was used. Ten grams of sample were weighed into a calibrated measuring cylinder, and the volume was noted for loose bulk density (Equation1). The cylinder's bottom was then repeatedly tapped onto a firm pad on a laboratory bench until a constant volume was observed and the dense volume was captured. The packed bulk density is calculated as the sample weight per volume after tapping (Equation2).

About ten grams of the sample was weighed into a 100 ml measuring cylinder, distilled water was added to reach a volume of 100 ml. The sample was stirred vigorously and allowed to stand for three hours. The volume of settled particles was recorded and subtracted from 100, and the difference is reported as percentage dispersability as expressed in Equation3 [36].

%Dispersability = 100 – the volume occupied by the flour--------Equation3

The standard methods described by [32] were adapted in the determination of total dietary fibre (TDF) and soluble dietary fibre (SDF); the insoluble dietary fibre (IDF) content was calculated by the difference between the TDF and SDF (Equation4) from where the ratio of the SDF to IDF was derived.

%IDF = %TDF - %SDF.--------Equation4

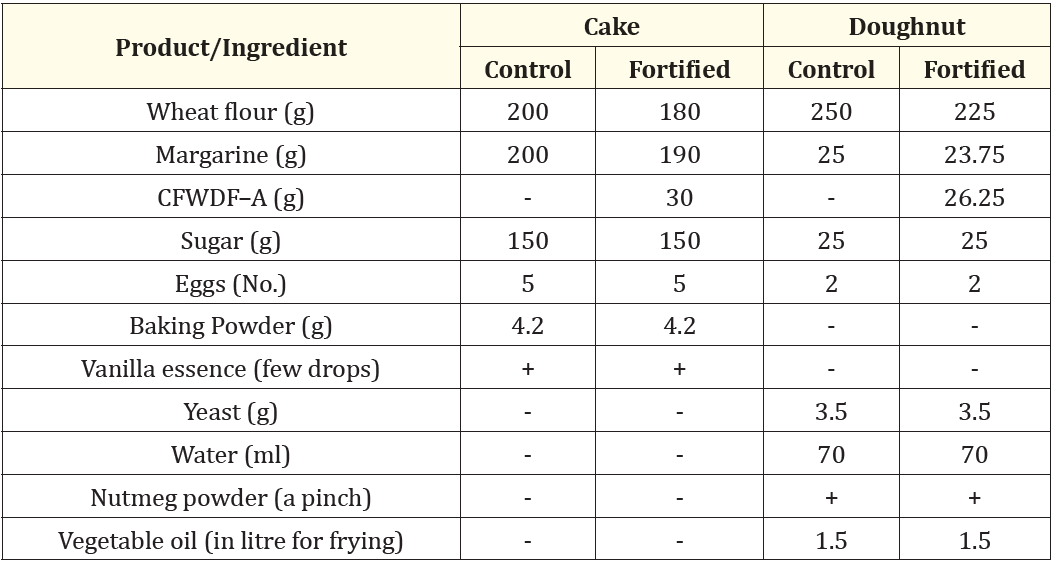

Cakes were made with a slight modification of the standardised recipe (Table 2) and methods described by [37]. The sugar and margarine were whipped to form a fluffy cream in a mini food mixer (KENWOOD; KVL61, CHINA). Likewise, the eggs were beaten and manually whipped to a homogenous consistency in a plastic container, and vanilla essence was added as flavouring to the whipped beaten eggs. Wheat flour and baking powder were mixed in a bowl, and the egg mixture was alternately added to the cream and mixed to a smooth consistency. The formed batter was dispensed into a pregreased baking tray and baked in a preheated oven at 150±5ºC for 20 min. The same procedures were followed for the citrus fruit waste dietary fibre (CFWDF) fortified cake except that wheat flour and margarine were partially replaced with 10% and 5% dietary fibre, respectively.

Doughnuts were made with slight modifications of the standardised method and recipe (Table 2) provided by [38]. The margarine was manually rubbed into the mixture of dry ingredients (wheat flour, sugar, and nutmeg powder) in a small mixing bowl. The yeast with a little part of the sugar was combined with 5 tablespoons of warm water in a small bowl, covered, and placed in a warm location for activation. The beaten egg, yeast batter, and water were combined with the flour mixture in a large mixing bowl and thoroughly mixed for about 10 minutes to form a smooth dough which was folded into a rough ball; covered with a clean black nylon, and placed under the sun for about 1 h: 30 min for proofing until it rise and about doubled the size. Then, it was placed on a floured surface and knocked back with the palm, and a small amount of flour was rubbed on the sticky dough during the process. Obtained dough was cut into rounds of smaller sizes and allowed to proof further for about 20 minutes before being fried in the preheated oil

![Table 2: Recipes for the Control and CFWDF-Fortified Products.

CFWDF-A = Citrus fruit wastes dietary fibre-Segment walls;- = Not added; + = Added

Sources: Sharoba., et al. (2013) [37]; Dawood., et al. (2015) [38].](https://actascientific.com/ASNH/images/ASNH-08-1433_table2.PNG)

Table 2: Recipes for the Control and CFWDF-Fortified Products. CFWDF-A = Citrus fruit wastes dietary fibre-Segment walls;- = Not added; + = Added Sources: Sharoba., et al. (2013) [37]; Dawood., et al. (2015) [38].

At about 180°C until it turned golden brown. An oil test for frying readiness was carried out by dropping a small amount of dough into the oil to see how quickly it fried. Finally, the doughnuts were removed from the frying oil and drained of excess oil using a perforated spoon, cooled, and packaged. Here, the same procedures were followed for the citrus fruit wastes dietary fibre fortified doughnuts where the wheat flour and margarine were partially replaced with 10% and 5% dietary fibre, respectively.

The percentage proximate composition (moisture, crude protein, total ash, fat, and crude fibre contents) was determined by the standard methods of [39], and the carbohydrate content was calculated by the difference (Equation5a). Atwater factors were used to calculate the total energy value (Kcal/100g) of the fast food products as shown in Equation5b [40].

Carbohydrate = 100-[moisture + protein + total ash + fat + total dietary fibre] g/100g (dw) --------- (Equation5a)

Total Energy value (Kcal/100g) = [(protein x 4) + (crude fat x 9) + (carbohydrate x 4)] ------------- (Equation5b)

The L, a, and b, generally referred to as Lab colour were evaluated using a colorimeter (Chroma meter CR410; Konoca Minolta Sensing Inc; Japan). The Lab assessed the following colour traits: the ‘L’ (lightness) axis has 0 as black, while 100 is white; the ‘a’ (red-green) axis has positive values as red while negative values are green, and 0 is neutral; and ‘b’ (yellow-blue) axis has positive values as yellow while negative is blue, and 0 is neutral. Triplicate measurements of L, a, and b parameters were done on the samples and the Hunter Lab system was used to express the results [41].

The procedure of [42] was followed for the sensory analysis. Twenty consented, semi-trained panelists [6,38] drawn from the staff and final year students of the University where the work was conducted who were not allergic to any of the ingredients were used for the evaluation. Those who may be allergic (especially lactose intolerant or celiac patients) were excluded from the analysis to avoid health implications. The panel comprised eight males and twelve females within the age bracket of 19-34 years. No coercion was involved and each panelist was free to withdraw at any point during the evaluation. Sensory attributes of appearance, crust, texture, aroma, taste, mouth feel, and overall acceptability were evaluated. All the ratings were done on a 9-point hedonic scale, with 9 being “like extremely” and 1 “disliked extremely”, rejection was taken at point 4 and below. The evaluation was done in a distraction-controlled environment with consistent lighting and good ventilation. The coded samples were presented to the panelists separately with potable water to rinse their mouths after each evaluation, and the scoring sheet was given to record their preferences.

Descriptive analysis was used in the statistical treatment of the data obtained in the experiment while the T-test was used to establish differences among treatments using SPSS version 21. Significance was accepted at p < 0.05.

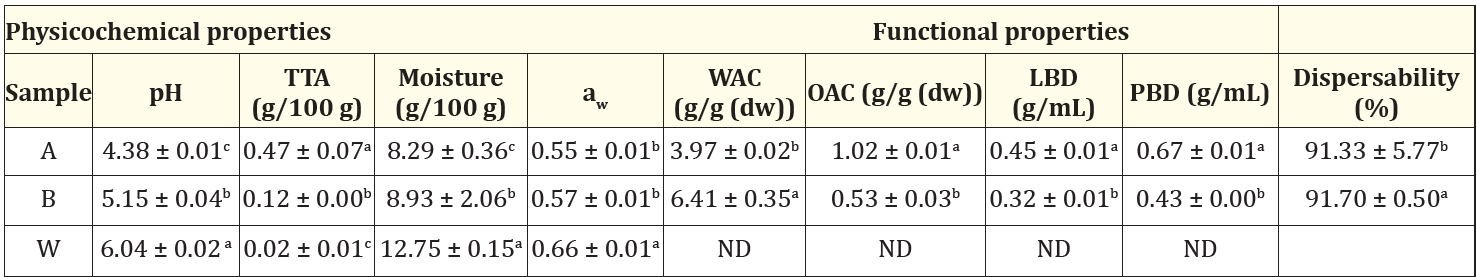

The physicochemical and functional properties of citrus fruit waste dietary fibre powder mix are presented in Table 3. The lowest pH (4.38) in sample A could be a result of residual ascorbic acid (vitamin C) from the fruit during juice extraction while that of B (5.15pH) and W (6.04pH) are comparable to the lower range (5.77pH) reported by [43] for wheat and coconut flour blend. Generally, the low values of TTA (0.47g/100gA and 0.12g/100gB) for the citrus waste powders imply that the fortified product will be less acidic which should be desirable, especially for an ulcer patient. The low range of moisture content (8.29-8.93g/100g) and water activity (aw) (0.55-0.57) for both segment walls (A) and pith (B) powders respectively, implies stability against microbial proliferation which also aided the ease of handling during the food application. This commemorates the report of [44]. However, the wheat flour (W) had a higher moisture (12.75g/100g) and aw (0.66) which could be of a less stability.

The functional properties of citrus waste dietary fibre (samples A and B) showed (3.97 and 6.41g /gWAC) and (1.02 and 0.53g/gOAC) respectively that could support good dough formation for quality baking as well as impacting good mouth feel on the fortified fast food products (Adebowale and Lawal, 2004) [45]. The water absorption capacity (WAC) and oil absorption capacity (OAC) determines the amount of water and oil the flour will absorb during mixing and dough formation in bakery products (Mironeasa and Codină, 2013) [30]. Loose (LBD) and packed bulk densities (PBD) for the citrus waste dietary fibres (A and B) were recorded at (0.45 and 0.32g/mL) and (0.67 and 0.43g/mL), while the dispersability was observed at (91.33 and 91.70%), respectively. According to Wang., et al. (2015) [46], bulk density in terms of LBD and PBD is usually affected by the particle size and density of the flour, it is important in determining the packaging requirement, materials handling, and application in food preparation. The low values obtained for LBD and PBD in the present work could prevent the heaviness of the fortified products. The functional properties as obtained in the present work are comparable to the values reported in the literature for various composite flours experimented for bakery products [43,47-49].

Table 3: Physicochemical and functional properties of citrus fruit wastes fibre mix.

Values are means of triplicates determinations ± standard deviation; means with different superscripts within the same column are significantly different (p < 0.05)

A = Mixture of segment wall of different citrus fruit wastes; B = Mixture of pith (albedo- whitish spongy part) of different citrus fruit wastes; TTA = Titratable acidity; aw = Water activity; WAC = Water absorption capacity; OAC = Oil absorption capacity; LBD = Loose bulk density; PBD = Packed bulk density; dw = Dry weight; ND = Not Determined

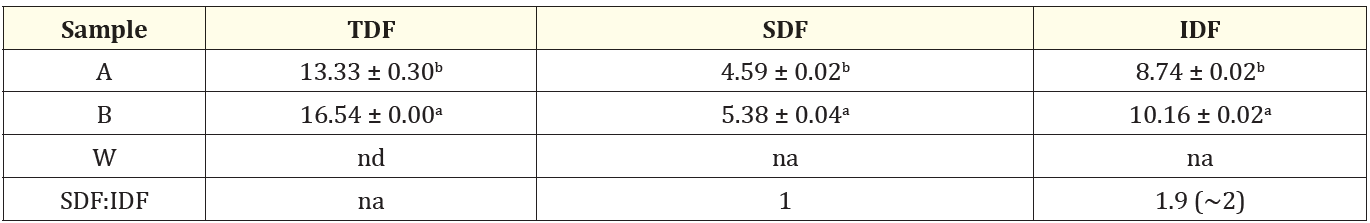

The soluble and insoluble dietary fibre ratio of citrus fruit waste dietary fibre powder mix is presented in Table 4. Dietary fibre plays critical roles in reducing postprandial glucose and cholesterol levels, and maintaining gut health [37] and it is often divided into soluble (SDF) and insoluble dietary fibre (IDF). The soluble dietary fiber in food can absorb glucose in the human system leading to the reduction of postprandial blood glucose and the risk of diabetes mellitus [26] and the insoluble portion helps in bowel movement and maintenance of gut health [27]. To be considered a food ingredient, the dietary fibre source should have an SDF/IDF ratio close to 1:2 [1,50]. In the present work, the dietary fibre mix samples (A and B) met the standard ratio 1:2 for SDF: IDF as acceptable food ingredients and index of good functional

Table 4: Soluble and insoluble dietary fibre (%) ratio of of citrus fruit wastes fibre mix. Values are means of triplicates determinations ± standard deviation; means with different superscripts within the same column are significantly different (p < 0.05) A = Mixture of segment wall of different citrus fruit wastes; B = Mixture of pith (albedo- whitish spongy part) of different citrus fruit wastes; W = Commercial wheat flour as reference sample; TDF = Total dietary fibre; SDF = Soluble dietary fibre; IDF = Insoluble dietary fibre; nd = Not detected; na/- = Not applicable

properties [5]. The total (TDF), soluble (SDF), and insoluble dietary fibre (IDF) constituents of the mixed citrus fruits wastes dietary fibre sample A had (13.33, 4.59 and 8.74%) and sample B had (16.54, 5.38 and 10.16%) respectively presenting sample B higher in dietary fibre components than sample A. The TDF was below the detectable level in the commercial wheat flour (W) which may be due to the milling process. This agreed with the findings of [6] who reported that wheat flour lost its dietary fibre constituent (the bran) to the milling process. This shows the necessity for fortifying refined wheat flour products (especially pastry fast foods) with dietary fibre.

Although sample B had a higher TDF, SDF, and IDF than sample A, it was discontinued for the fortification experiment due to so much bitter taste imparted unto the fast food products during the preliminary sensory evaluation even at the lower percentage dosages tried showing correlation with the report of [3].

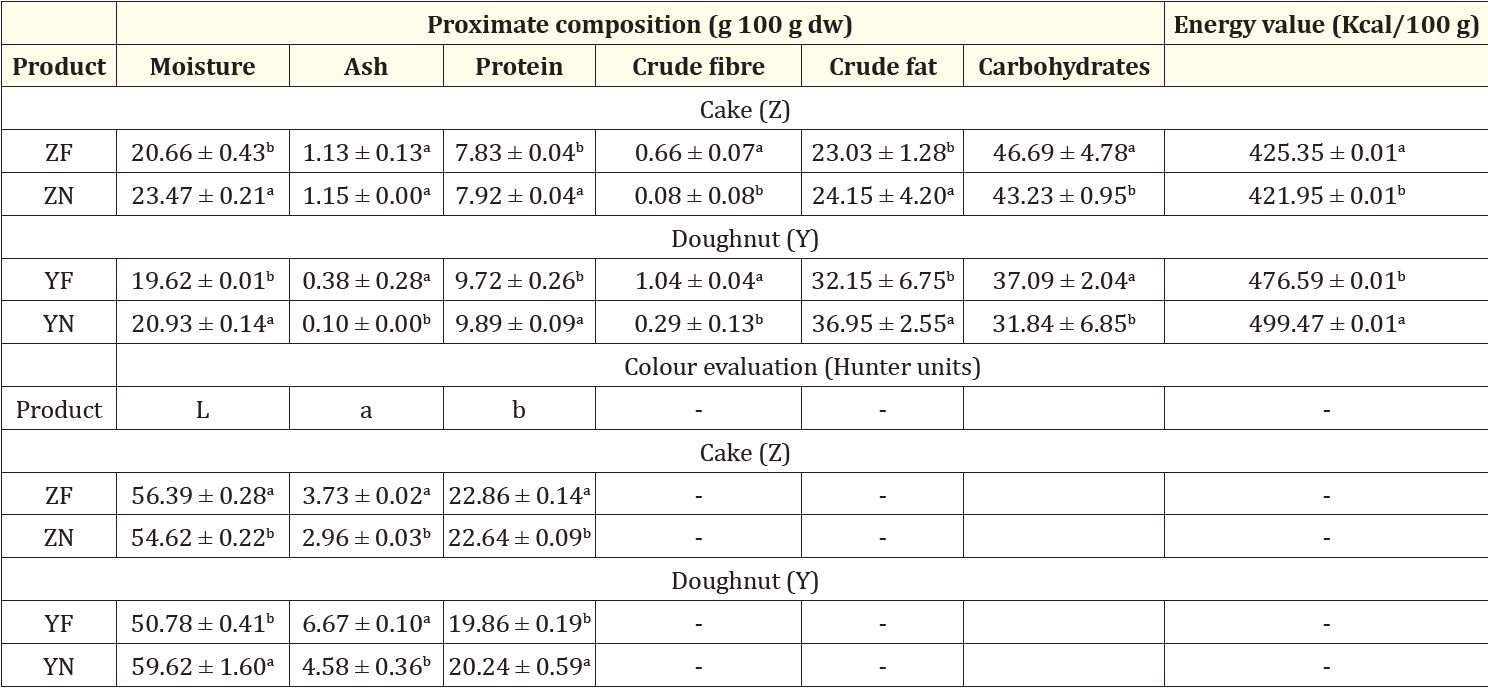

The result obtained for the proximate, total energy value and colour analyses of the cake and doughnut is presented in table 5. There were significant (p < 0.05) differences among the products in all the parameters (except the ash of the cake). The fortified products had significantly lowered moisture contents (20.66 and 19.62g/100g dw) for cake and doughnut respectively than the corresponding control samples (23.47 and 20.93g/100g dw). This could be due to the inclusion of citrus waste fibre powder and the subsequent increase in the total solid contents which may support the shelf life of the fortified products. This is in line with the report of [3]. A non-significant (p > 0.05) different values (1.13 and 1.15g/100g dw) were recorded for ash content in the fortified and control cake respectively, which is comparable with the findings of [5] in the 10-15% inclusion of citrus fibre in cake (1.34-1.91%ash). However, fortified doughnuts had a significantly higher ash content (0.38g/100g dw) than the control (0.10g/100g dw) and are relatively comparable to the lower range of value (0.70%ash) reported by [6] for cookies supplemented with jackfruit rind fibre. The ash content of a food product is an index of the mineral composition [6].

The protein values ranged from (7.83-9.89g/100g dw). Fortified products recorded lower protein contents than the corresponding control products. This may be due to the partial replacement of wheat flour with citrus waste fibre and invariably the corresponding reduction in gluten content (source of protein) of the composited flour used for the fortified products. The values obtained for protein content concurred with the reports of [5] and [6]. On the other hand, the crude fibre contents of the fortified fast foods (0.66 and 1.04g/100g) were significantly improved over the control (0.08 and 0.29g/100g) in both cake and doughnut respectively; implying an improvement in the nutritional value. Since the TDF in wheat flour was below a detectable level (Table 3), the source of crude fibre improvement in the fortified products could be traced to the added citrus fruit waste dietary fibre powder, supporting the potential health benefits of the fortified products. Also, the crude fibre content of the fortified fast foods in the present work (0.66g/100g cake and 1.14g/100g doughnut) is relatively higher than the lower range of value (0.56%) reported by [10] for the selected common conventional fast foods sold in Nigeria but lower than those obtained for fibre supplemented cake and cookies in the works of [5] and [6] respectively. The sources of these variations could range from no fibre inclusion, and varied recipes, to different fibre sources involved in these works. Notwithstanding, the increased fibre and ash (index of mineral elements) contents against the control products in the present work indicate the nutritional improvement of the fortified products and the consequent potential health benefits claim as noted by [51]. Dietary fibre in foods aids bowel movement and gut health maintenance [27].

The crude fat contents for the fortified cake and doughnut; (23.03 and 32.15g/100g), respectively, were significantly (p < 0.05) lower than those of the corresponding control samples (24.15 and 36.95g/100g). This may be due to the partial replacement of fat with the citrus waste dietary fibre in the fortified products. The carbohydrate contents range from 31.84-46.69g/100g; also with significant (p < 0.05) differences within the fortified and control products. Generally, the observed proximate composition in the present work is in line with the report of [6] for cookies supplemented with 10-15% jackfruit rind fibre and that of [5] in cake fortified with citrus fibre.

The calculated energy value from the determined protein, fat, and carbohydrate contents of the fast food products ranged from (421.95-499.47 Kcal/100g). There was a significant (p < 0.05) reduction in the energy value of the CFWDF-fortified doughnut, suggesting its potential lower-glycemic index and health benefit against the control. This concurred with the report of [4], that citrus by-products are a non-caloric bulking agent. Notwithstanding, a higher level of inclusion of CFWDF may be required to fortify the cake to produce the same effect on the energy value. However, its presence at the current level contributed to nutritional improvement, especially the fibre content that could aid other potential health benefits such as gut health maintenance and bowel movement.

Table 5: Proximate composition, total energy value, and colour analysis of fast food products Values are means of triplicates determinations ± standard deviation; means with different superscripts within the same column are significantly different (p < 0.05). dw = Dry weight; ZF = Cake fortified with citrus wastes dietary fibre; ZN = Cake with no fortification (control); YF = Doughnut fortified with citrus wastes dietary fibre; YN = Doughnut with no fortification (control); L = Lightness axis; a = Red-green axis; b = Yellow-blue axis; - = Not applicable

Significant (p < 0.05) differences existed in the entire colour parameters for the products. The CFWDF positively impacted the Lab properties in the cake where the values were higher in the fortified than the control, but the reverse trend was followed for ‘L’ and ‘b’ values in the doughnut. However, the ‘a’ value was higher in fortified cake and doughnuts than in the control products. Comparable values were observed in ‘L’ and ‘b’ values in the cake and doughnut but the ‘a’ values were lower in the cake than in the doughnuts. The differences observed in the colour parameters between the two products might be due to the different processing operations (baking and frying) involved in the preparations.

Sensory quality of fast food products is shown in Table 6. All the determined attributes in the entire products were approximately found at the levels of ‘like moderately’ (7) to ‘like very much’ (8) by the panelists on the 9 points hedonic scale used. There was no significant (p > 0.05) difference in the overall acceptability of the fortified and control cake while that between the doughnut products was not so pronounced. The result showed that fortification with citrus fruit wastes dietary fibre at the percentage (15%) used was effective for the sensory acceptability of the CFWDF fortified cake and doughnut. This conforms to the report of [5] with a 10% inclusion of citrus fibre in a cake but in contrast with the findings of [6] where the inclusion of jackfruit rind fibre in cookies at 10-15% was not acceptable except only at 5%.

Table 6: Sensory quality of fast food products. Values are means of triplicates determinations ± standard deviation; means with different superscripts within the same column are significantly different (p < 0.05) ZF = Cake fortified with citrus wastes dietary fibre; ZN = Cake with no fortification (control); YF = Doughnut fortified with citrus wastes dietary fibre; YN = Doughnut with no fortification (control)

The results of this work have shown that the produced citrus fruit waste dietary fibre (CFWDF) powders met the standard specification ratio of 1:2 for SDF: IDF to be used in the food system. The CFWDF-A was effective in improving the nutritional value of fast foods and potent in reducing the caloric index (energy value) for the health benefits of the fortified doughnut. Hence, the rate of human health disorders through frequent consumption may be eased without changing habits. Additionally, application in fast food fortification added value to citrus fruits wastes and a 10% wheat flour substitution will contribute to minimising the overall total dependence on wheat importation in Nigeria for economic benefit. A higher percentage of the citrus fruit wastes dietary fibre inclusion than used in the present work may be required to reduce the caloric intake in the cake. This will further lessen the burden of over-dependence on wheat flour for pastries in Nigeria.

The authors at this moment acknowledge the support of the Management of Mountain Top University for the permission granted to use their modern laboratory facilities in carrying out this research.

The author declares that this work has no financial or conflict of interest.

Copyright: © 2024 Dupe Temilade Otolowo., et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.