Chakranarayan Ankita1*, Torane Sanjaykumar2, Bachhao Kiran3 and Nikam Yogesh4

1Assistant Professor, Department of Agricultural Economics, COA, Dhule, MPKV, Rahuri, (MS), India

2Head, Department of Agricultural Economics, Director of Research (AE) DBSKKV, Dapoli (MS), India

3Ph.D. Scholar, Department of Agricultural Economics DBSKKV, Dapoli (MS), India

4Ph.D. Scholar, Department of Agricultural Economics MPKV, Rahuri (MS), India

*Corresponding Author: Chakranarayan Ankita, Assistant Professor, Department of Agricultural Economics, COA, Dhule, MPKV, Rahuri, (MS), India.

Received: August 22, 2024; Published: September 09, 2024

Citation: Chakranarayan Ankita., et al. “Economic Analysis of Value Addition in Paddy Processing in North Konkan Region of Maharashtra, India". Acta Scientific Agriculture 8.10 (2024): 11-16.

A comprehensive study was conducted to evaluate the economic aspects of value addition in capital requirements, costs, and returns associated with processed products of Paddy in the purposively selected North Konkan region of Maharashtra, India. Thirty Paddy processing units were chosen from the North Konkan region for the analysis. The per-unit capital investment in Paddy processing amounted to Rs. 39 lakhs, reflecting the substantial capital needed for these enterprises. The study revealed that the total cost, gross returns, and net returns in production were Rs. 529,581, Rs. 851,734, and Rs. 322,153, respectively. The input-output ratio was calculated at Rs. 1:1.61, indicating the profitability of Paddy processing enterprises in the region. The average working period for paddy processing was found to be 112 days, with an average of 9.48 laborers employed per factory per day. This resulted in the creation of employment for 1,077 days per year. Notably, Paddy processing units in the study area were found to operate above the breakeven point, further emphasizing the viability and profitability of these enterprises. The findings highlight the positive economic impact of Paddy processing, both in terms of returns and employment generation, contributing to the overall economic sustainability of the region.

Keywords: Paddy; Cost; Return; Processing; Value

Agriculture is the backbone of the Indian economy, providing essential ingredients to mankind and raw materials to the industrial sector. Achieving agricultural prosperity can foster economic advancement to a greater extent. According to the recent report of the Economic Survey, during the fiscal year 2021-2022, the agriculture and allied sectors' share in India's GDP was estimated to 19.0 per cent [1]. India stands as a prominent global player in the production, processing, and export of rice, securing its position as the second-largest paddy-producing country worldwide. Notably, India holds the title of the largest exporter, contributing over 40 percent to the global export market [2]. The paddy processing industry serves as a significant employment generator, providing livelihoods for over 10 lakh individuals across farms and factories in rural areas. Covering an extensive 47 million hectares of land, India annually produces 132 million tonnes of rice. Maharashtra, a leading state in rice production, contributes significantly, boasting a total rice crop area of 1.72 million hectares and a production of 9.56 million tonnes [1]. The Konkan region, renowned for its rice production, particularly stands out. Farmers in this region have upheld product quality and consumer goodwill, earning them recognition as a geographical indication.

This study aims to delve into the economic analysis of paddy processing, focusing on the economics, capital investment, break-even analysis, and value addition in this vital sector.

The North Konkan region, known for hosting the highest concentration of Paddy processing units, was purposefully selected to fulfil the study's objectives. Specifically, processing units from Palghar and Raigad Districts were randomly selected for inclusion. All selected units held registrations with the Food Safety and Standards Authority (FSSI), ensuring adherence to established safety standards. In alignment with the existing FSSI classification, the processing units were categorized accordingly in the current study. The methodology used was adapted from the study on the economic analysis of value addition in mango pulp processing in the Konkan region of Maharashtra [3]. The final sample comprised 30 processing units, with 15 units selected from each district for rice processing. Primary data essential to the study were acquired through the "Survey Method," utilizing specially designed and pre-tested schedules. To evaluate financial feasibility, analytical tools such as the Break-even point were employed to contribute valuable insights to this research endeavour.

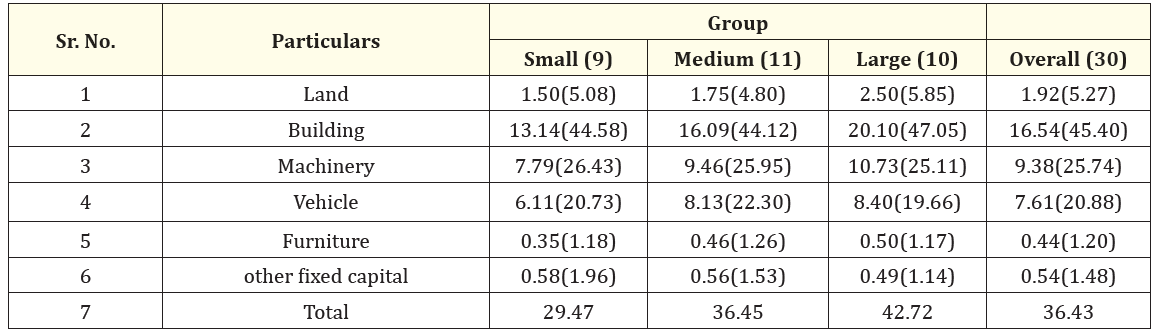

In the realm of paddy processing enterprises, a specified capital outlay is crucial, as outlined in table 1. The aggregate capital investment for paddy processing stands at Rs. 36.43 lakh. Breaking it down by size, small enterprises require a capital investment of Rs. 29.47 lakh, medium-sized enterprises Rs. 36.45 lakh and large enterprises Rs. 42.72 lakh.

Table 1: Capital investment in Paddy processing (Value Rs. lakh).

(Figures in parentheses indicate percentage to total).

Notably, the predominant share of the investment, amounting to Rs. 16.54 lakh (45.40%) is allocated to building infrastructure, while machinery accounts for Rs. 9.38 lakh (25.74%). The results are consistent with [4], highlighting the substantial financial investment needed for machinery and infrastructure in the capital-intensive paddy processing industry.

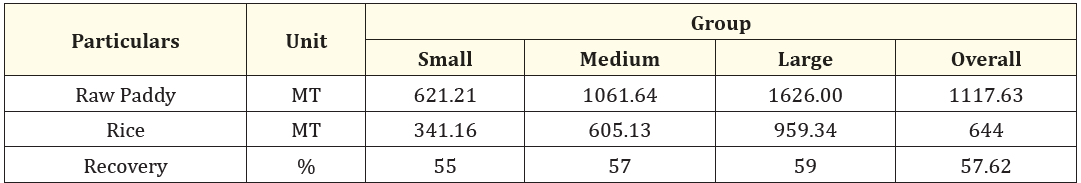

Table 2 provides information on paddy processing and rice recovery percentages. Overall, the quantity of paddy processed per unit was 1117.63 tons. Breaking it down by size, small enterprises processed 621.21 tons, medium-sized enterprises processed 1061.64 tons, and large enterprises processed 1626 tons. The study found that at the overall level, 1117.63 MT of paddy resulted in the production of 644 MT of rice, achieving a recovery percentage of 57.62%.

Table 2: Per unit paddy processing and recovery percentage of rice.

Notably, large-sized units exhibited the highest recovery percentage at 59%, followed by medium-sized units at 57%, and small-sized units at 55%. This analysis underscores that, on average, 1117.63 MT of paddy processing in the study area yields 644 MT of rice, with a significant recovery percentage of 57.62%.

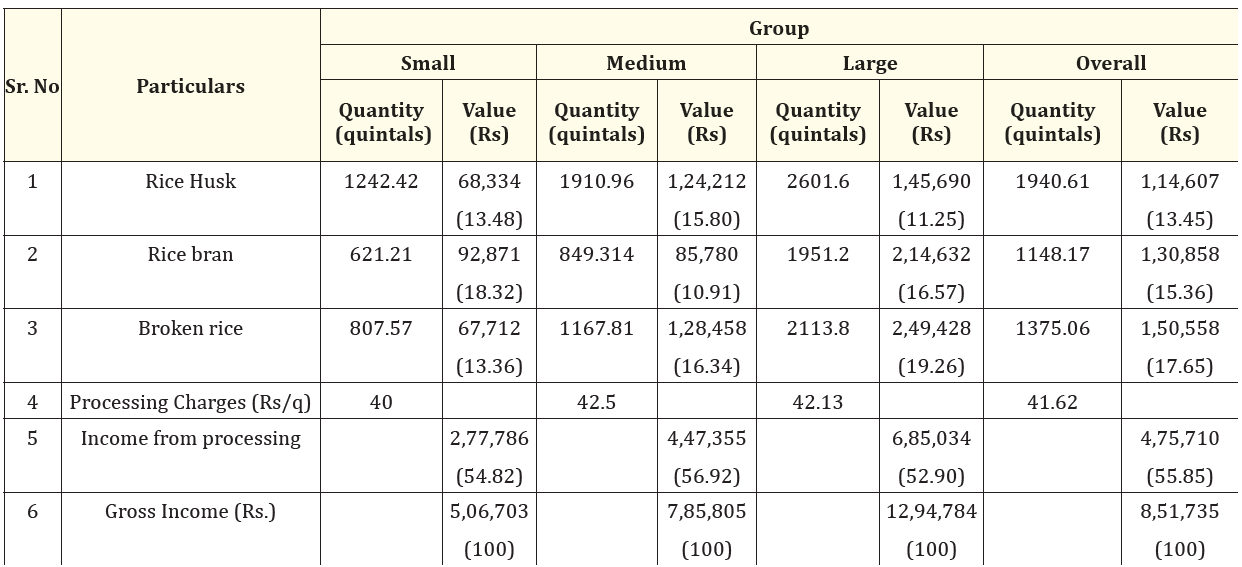

Table 3 details the per unit income of processors from paddy processing and their gross returns. The overall gross income for processors amounted to Rs. 851,735, with per unit income varying from Rs. 506,703 in small-sized units to Rs. 1,294,784 in large-sized processing units.

Table 3: Per unit production and returns in paddy processing.

(Figures in parentheses are percentage to Gross Income).

Table 3 elaborate on per unit income of processors from paddy processing and their gross returns. The overall gross income for processors amounted to Rs. 8,51,735, with per unit income varying from Rs. 5,06,703 in small-sized units to Rs. 12,94,784 in large-sized processing units. The study highlighted that processors in the area not only assist farmers and government agencies in paddy processing but also earn income per quintal of processed paddy. The primary sources of income for processors include processing charges and various by-products such as rice husk, rice bran, and broken rice. Notably, the total income was dominated by processing charges at 55.85%, followed by broken rice at 17.65%, rice bran at 15.36%, and rice husk at 13.45%. The by-product income percentage in the total income of processors was crucial, making up 46.46%, contributing significantly to the financial feasibility of the processing business. Processing charges varied among small, medium, and large groups, amounting to Rs. 27,786, Rs. 447,355, and Rs. 685,034, respectively. Other income from by-products such as rice husk, rice bran, and broken rice collectively accounted for Rs. 114,607 (13.45%), Rs. 130,858 (15.36%), and Rs. 150,558 (17.65%), respectively. The results are consistent with those of [5], which also indicate that value addition was highest in large processing units.

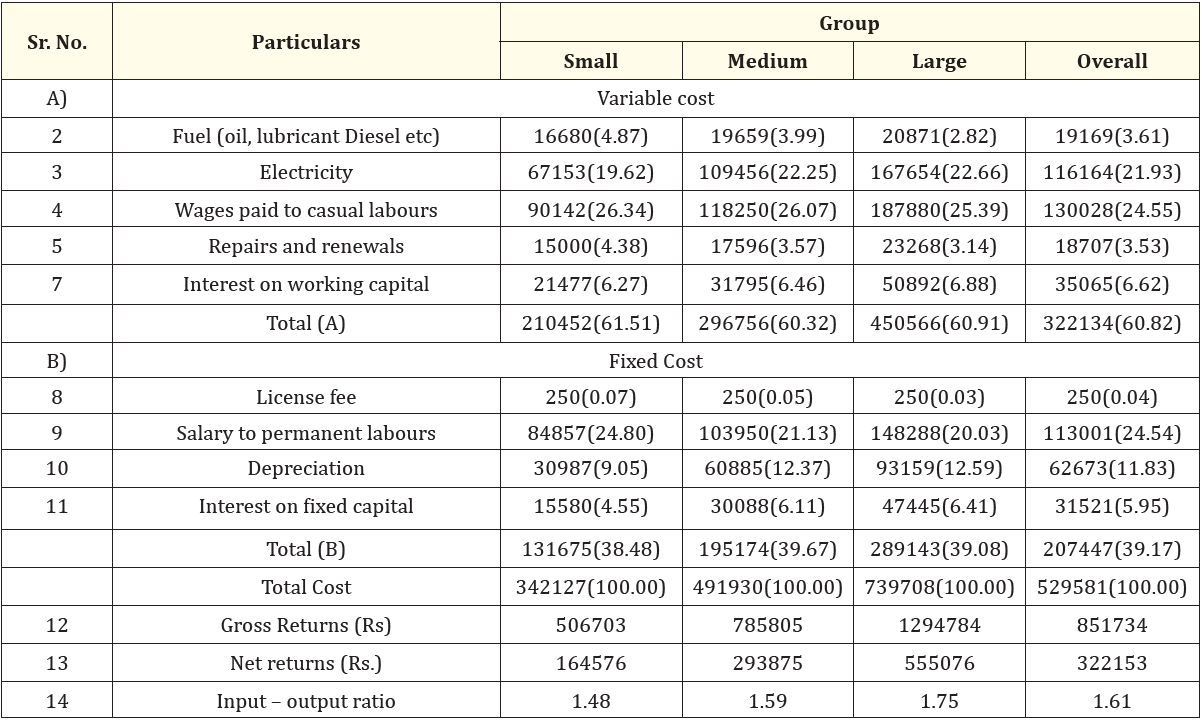

Table 4 provides insights into per unit costs and returns in paddy processing. At the overall level, the per unit total processing cost amounted to Rs. 529,581, with variable costs claiming the majority at 60.82% (Rs. 322,134) and fixed costs at 39.17% (Rs. 207,447). Notably, the largest components of the total cost were wages for casual labour (24.55%) and salaries for permanent labour (24.54%). Variable costs for small, medium, and large processor groups were Rs. 210,452, Rs. 296,756, and Rs. 450,566, respectively. Gross returns for these groups were Rs. 506,703, Rs. 785,805, and Rs. 1,294,784, with an overall gross return of Rs. 851,735 Results are in conformity with that of [6] the processors earn a good profit from paddy. The net returns per unit at the overall level were Rs. 322,153, resulting in an input-output ratio of 1.61. Further analysis showed that the net profit of processing units increased with the size of the unit, as evidenced by input-output ratios of 1.48, 1.59, and 1.75 for small, medium, and large groups, respectively. Results are in conformity with that of [6] Paddy processing is a profitable venture and its profitability increases with scale of production.

Table 4: Cost and returns in processing of Paddy (Rs).

(Figure in parentheses indicate percentage to total cost).

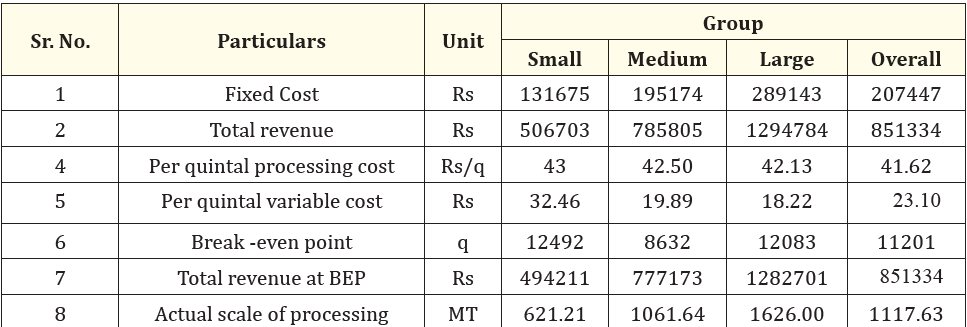

Table 5 shade lights on the breakeven point for paddy processing, indicating fixed costs and total revenue at the overall level of Rs. 207,447 and Rs. 851,334, respectively. The per quintal total processing cost and variable cost were Rs. 41.62 and Rs. 23.10, respectively. The breakeven point, representing the quantity at which costs match revenue from processing paddy, was determined to be Rs. 11,201 at the overall level. For small, medium, and large processor groups, the breakeven points 12,492 q, 8,632 q, and. 12,083 q, respectively. Result is associated with [7] It is worth noting that the actual production scale in each group surpassed their respective breakeven points, suggesting that production levels were sufficient to cover all costs allocated to paddy processing.

Table 5: Break-even point in Paddy processing unit.

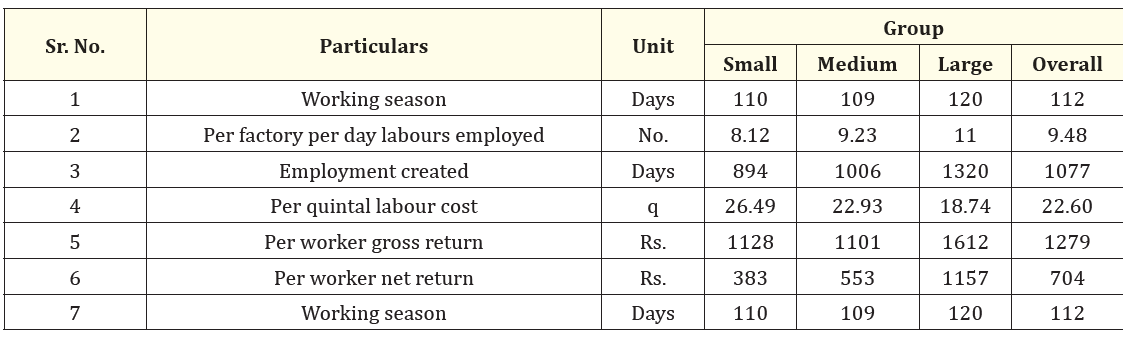

In the context of paddy processing, table 6 presents data on labor efficiency in the context of paddy processing. The average working season for paddy processing stood at 112 days, with variations observed across different groups. i.e. 110 days for small groups, 109 days for medium groups, and 120 days for large groups. The number of labor employed per factory ranged from 8.12 in small groups to 11 in large groups, indicating disparities in labor utilization. On average, 9.48 laborers were employed across all factories, resulting in a cumulative 1077 days of employment generated by processing units. Large groups demonstrated the highest potential for employment creation, generating 1320 days per factory, followed by medium groups with 1006 days and small groups with 894 days. The net returns per labour varied from Rs. 383 in small groups to Rs. 1157 in large groups, with an overall net return per labour of Rs. 704, underscoring efficient labour utilization across all groups. The labour cost per quintal at the overall level was Rs. 22.60. A similar result was observed in multiple studies, including references [5,7].

Table 6: Labour efficiency in paddy processing unit.

In summary, the study concludes that Paddy processing in the Konkan region of Maharashtra necessitates a relatively higher capital investment. However, it proves to be a profitable venture, particularly in the North Konkan region. The net returns from Paddy processing in this area amount to Rs. 322,153, with a commendable benefit-cost ratio of Rs. 1.61. Moreover, the findings reveal that Paddy processing units operate at a scale of 1117.63 MT, and the determined break-even point of 11,201 quintal suggests a significantly higher margin of safety. Consequently, Paddy processing emerges as an economically remunerative enterprise in the North Konkan region of Maharashtra, demonstrating its viability and potential for profitability.

Copyright: © 2024 Chakranarayan Ankita., et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

ff

© 2024 Acta Scientific, All rights reserved.