Navpreet Chhatwal1, Jayakar Shetty2 and K Chandrasekharan Nair3*

1Consultant Prosthodontist, Dove Dental Clinic, Mithapur Chowk, Jalandhar, India

2Former Professor, Department of Prosthodontics, AECS Maaruti College of Dental Sciences, Bangalore, India

3Professor Emeritus, Department of Prosthodontics, Sri Sankara Dental College, Akathumuri, Thiruvananthapuram, Kerala, India

*Corresponding Author: K Chandrasekharan Nair, Professor Emeritus, Department of Prosthodontics, Sri Sankara Dental College, Akathumuri, Thiruvananthapuram, Kerala, India.

Received: October 09, 2024; Published: October 31, 2024

Citation: K Chandrasekharan Nair., et al. “Comparison of Properties of Auto Polymerizing Polymethyl Methacrylate Resin and Bis-Acryl Composite Resin Used for Interim Restorations - an In vitro Study". Acta Scientific Dental Sciences 8.11 (2024):92-99.

Objectives: 1. To compare the properties viz. flexural strength, deflection, impact strengthand surface hardness of auto-polymerizing polymethyl methacrylate and bis-acryl composite resins. 2.To compare the surface roughness of auto-polymerizing PMMA and bis-acryl composite resin before and after polishing.

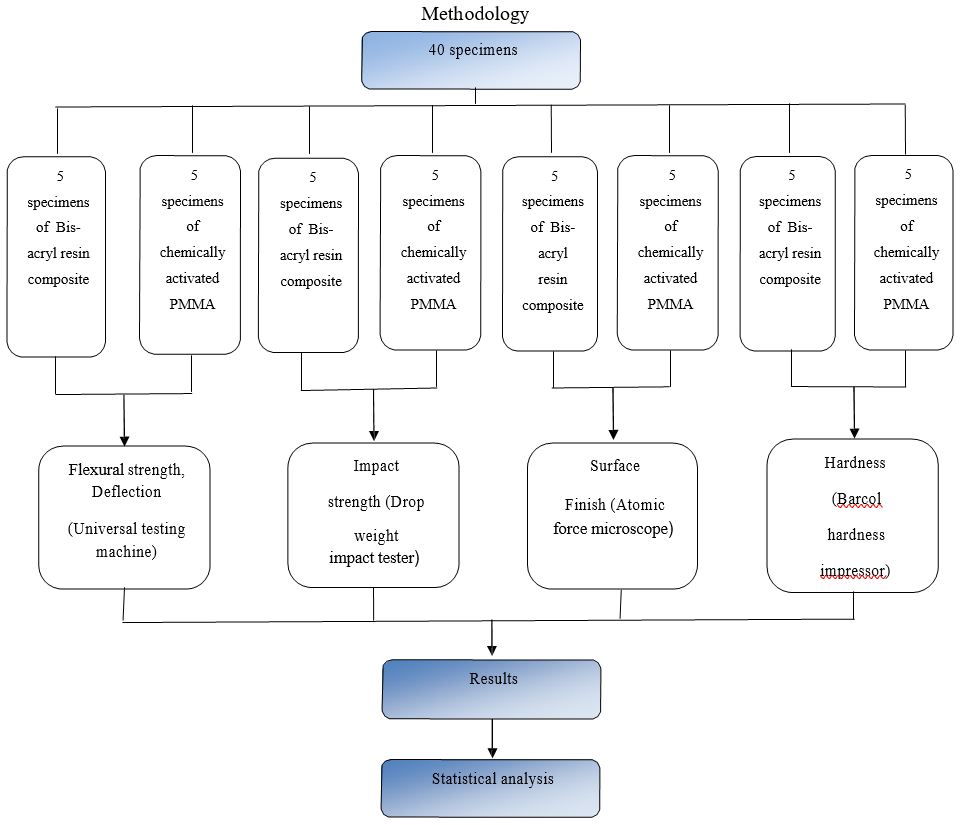

Methodology: Samples measuring 127 x 12.7 x 3mm were made for testing flexural strength and deflection of auto-polymerizing polymethyl methacrylate (DPI) and Bis –acryl composite resin (Protemp-3, 3M ESPE) using universal testing machine. Impact strength, hardness and surface roughness were measured using specimens measuring 90 x 90 x 3mm. Impact strength was measured using drop weight impact tester, hardness was measured using Barcol hardness tester and surface roughness with Atomic force microscope respectively. Results were analysed statistically with t-test.

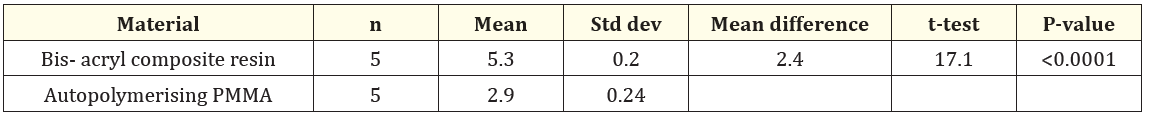

Results and Conclusions: Mean flexural strength value of Bis-acryl composite resin was 71.5 ± 1.52 MPa and that of autopolymerising PMMA was 49.2 ± 2.17 MPa. The mean deflection value of Bis-acryl composite resin was 5.3 ± 0.2mm and that of autopolymerising PMMA was 2.9 ± 0.24mm. These values are comparable to other studies.

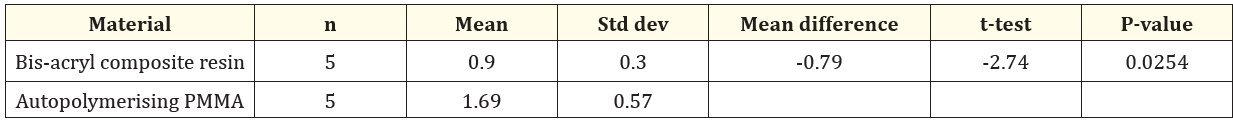

Impact strength of Bis-acryl composite resin was observed as 0.9 ± 0.3 Joules and that of autopolymerising PMMA was 1.69 ± 0.57 Joules. PMMA had significantly high impact strength than that of Bisacryl composite resin.

Bis-acryl composite resin showed higher surface hardness values of 41.6 ± 1.14 (Barcol) than that of autopolymerising PMMA which was 28.4 ± 1.8 (Barcol). Bisacryl resins can resist formation of scratches and thereby discoloration.

Surface roughness values of unpolished Bis-acryl composite was 533.4 ± 110.8nm and of unpolished autopolymerising PMMA was 3394 ± 1747nm. Surface roughness values of polishedBis-acryl composite resin was 651 ± 132.6nm and that of polished chemically activated PMMA was 555.2 ± 151nm. By employing polishing, surface roughness of bis acryl composite increased and the roughness values of PMMA decreased. Bis acryl resin does not require polishing and PMMA on the contrary definitely needs polishing. Bis-acryl composite resin showed higher values for flexural strength, deflection and hardness as compared to autopolymerising PMMA. Autopolymerising PMMA showed high impact strength as compared to Bis–acryl composite resin.

Keywords: Autopolymerizing PMMA; Bis-acryl Composite Resin; Flexural Strength; Deflection; Impact Strength; Hardness; Surface Finish; Atomic Force Microscopy

Interim restorations in fixed prosthodontic practice are important because of the protective role as well as the role in functional and aesthetic maintenance. Auto polymerizing acrylic resin (PMMA) has been the first choice for quite a long time in the fabrication of interim or provisional restorations. PMMA used to provide reasonable strength, aesthetics and harmonious biologic behavior with the oral tissues. The processing shrinkage and the weakness expressed when used in smaller sections are considered as undesirable properties of the PMMA resin. The high polish, PMMA used to gain could prevent plaque accumulation and gingival inflammation. This resin falls under the mono methacrylate group [1,2].

Bis-acryl resins are comparatively new entrants into the field of interim restorations and which belong to the group of dimethacrylates. Bis-acryl resins are composed of a polymer matrix, fillers and coupling agents. The presence of fillers has reduced the shrinkage when compared to that of PMMA. The mechanical properties also have increased considerably. While self cure PMMA exhibits a flexural strength of 101.18 MPa, Bis-acryl shows 211.44 MPa [3-6].

Provisional restorations, though intended for an interim period, should withstand occlusal load during mastication. Our standard testing methods do not simulate oral environment but provides a guideline in the selection of appropriate material. The resin type as well as the chemical composition dictate the mechanical properties like flexural strength and deflection of the interim restorations. To ensure long term service, the interim resins should be adequately polymerised. In fact, the monomer-polymer conversion can be evaluated by determining the surface hardness of the material. Hardness would indicate the material’s wear resistance as well as the wear of the opposing natural tooth. The interim restoration should also resist the abrasion of dentifrices and tooth brushes. A hard surface has the advantage of retaining the surface finish of the interim restoration. PMMA gets superior surface finish with conventional polishing techniques like tungsten carbide trimmers, pumice on muslin wheels and dry wool buffs. But this practice does not apply to Bis-acryl resins according to the manufacturer. A fact finding on what happens to the surface of Bis-acryl resin if conventional polishing techniques are applied has not been done in the Indian context. However, new generation of Bis-acryl resins appear to withstand polishing techniques because of the modified filler particle structure.

In the context of the fact that many studies have not been conducted on popular products available in the Indian market and used by the practising professionals, the present study was designed and conducted to compare the properties of autopolymerising acrylic resin and bis-acryl resin which are used in the fabrication of interim fixed restorations with the following objectives:

The present study was conducted to compare the properties of bis-acryl and autopolymerising PMMA resins used in the fabrication of provisional crowns and bridges viz. flexural strength, deflection, impact strength, hardness and surface roughness according to ASTM standards. Two resins were used to compare the properties viz. 1. Bis-acryl composite resin – Protemp 3 Garant (3M ESPE), 2. Autopolymerising acrylic resin – tooth moulding (DPI)

Specimens measuring 127 x 12.7 x 3 mm were fabricated in Bisacryl composite resin (Protemp 3 Garant – 3M ESPE) and in Autopolymerising PMMA resin – tooth moulding (DPI). Moulds were prepared in plaster loaded in a maxillofacial flask using stainless steel blanks. Resins were packed in the mould and processed. Five Bis acryl and five PMMA specimens were fabricated.

Each specimen was placed on the support of Instron Universal testing machine at 50-mm span for three-point flexural strength test. Flexural load was applied at a crosshead speed of 5mm per minute. Flexural strength was calculated in MPa and the deflection was recorded in mm (Figure 1).

Figure 1: Instron universal testing machine.

Specimens measuring 90 x 90 x 3 mm were fabricated using a process similar to that adopted for flexural strength specimens. Five specimens were fabricated in each resin to be used in the test of impact strength. Impact strength was tested with Drop weight impact testing machine (Instron dynatup 8250). 2.5kg drop weight was used and the tip of impactor was 15.5mm diameter. The load and energy parameters were measured through the load transducer incorporated in the impactor (Figure 2).

Figure 2: Drop weight impact tester

90 x 90 x 3 mm specimens were made from both Bisacryl and PMMA resins and hardness was measured using Barcol hardness tester. It has an indenter that penetrates the surface and measures the hardness directly (Figure 3)

Figure 3: Barcol hardness tester.

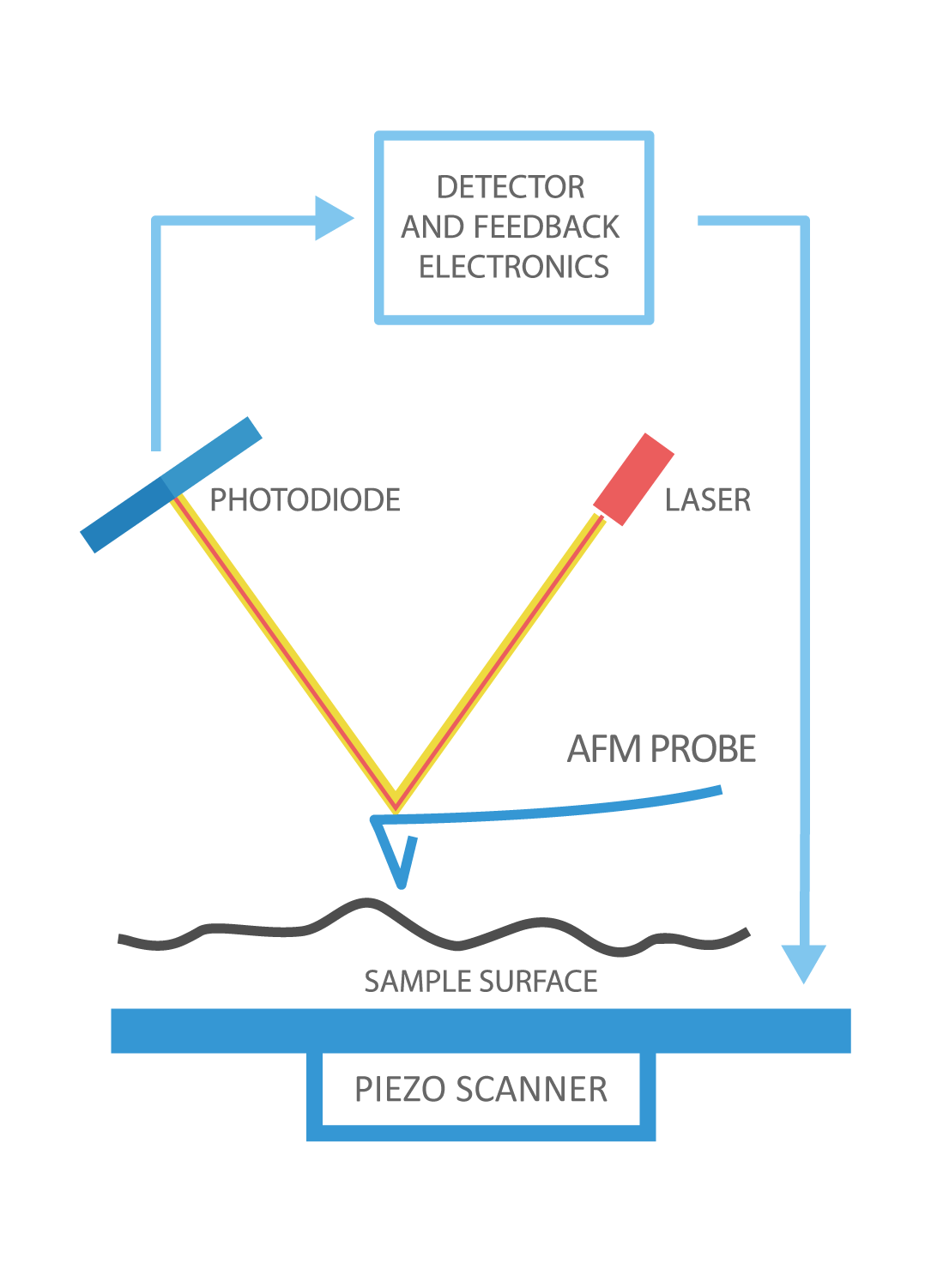

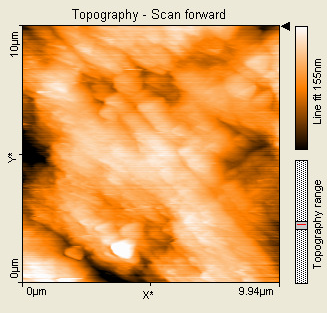

Specimens measuring 90 x 90 x 3 were fabricated in Bisacryl and PMMA resins following the methods already described. Surface roughness of five samples of each resin was measured using Atomic Force Microscopy (AFM). It can quantitatively measure in the x, y and z directions of the surface in nanoscale resolution. Tapping mode was used. A flexible cantilever sharp probe was used to scan the surface of the sample. The deflection of the probe is tracked by a laser beam and is directed into a position sensitive photo detector. It does this at extremely high resolution and the smallest variation on the surface topography is detected. 2D or 3D images can be obtained.

Both PMMA and Bis-acryl specimens were polished conventionally using tungsten carbide trimmers, sand paper and pumice paste on rag wheel. Before and after polishing, surface roughness was evaluated with Atomic Force Microscopy (AFM). Bis- acryl resins do not require polishing as per the manufacturer’s instruction. However, it was polished to maintain equality in methodology (Figure 4, 5). The methodology is depicted in the flow chart (Figure 6).

Figure 4: Atomic force microscopy assembly

Figure 5: Atomic force microscope - schematic diagram.

Figure 6: Flow chart on methodology.

Results were tabulated and were subjected to statistical analysis using t-test.

Two provisional restorative materials viz. Bis-acryl composite resin and autopolymerising PMMA were selected for the study. The following properties like flexural strength, deflection, Impact strength, Surface hardness and surface roughness of unpolished and polished resins were evaluated and compared. The results are presented in tables 1 to 7.

It was observed that there is a statistically significant difference in the mean flexural strength

of the two resins (P< 0.0001). Higher flexural strength was observed with Bis- acryl composite resin (71.5 ± 1.52 MPa) than with auto polymerising PMMA resin (49.2 ± 2.17 MPa) and the difference in mean flexural strength between them was statistically significant (<0.0001). (Table 1). Similarly higher deflection values were obtained with Bis acryl resin (5.3 ± 0.2mm) than with autopolymerising PMMA resin (2.9 ± 0.24mm) and it was statistically significant (<0.0001) (Table 2).

Table 1: Analysis of flexural strength (MPa).

Table 2: Analysis of deflection (mm).

Higher Impact strength was observed with autopolymerising PMMA (1.69 ± 0.57 Joules) than with Bis-acryl composite resin (0.9 ± 0.3 Joules) and the difference was statistically significant (p 0.0254). (Table 3).

Table 3: Analysis of Impact strength (Joules).

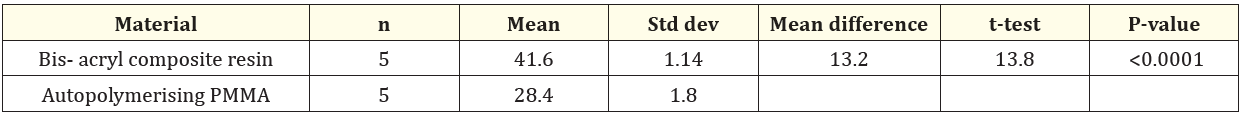

Bis acryl composite showed higher Barcol hardness values (41.6 ± 1.14) when compared to PMMA (28.4 ± 1.8). The difference in Barcol hardness values was statistically significant (<0.0001). (Table 4).

Table 4: Analysis of hardness (Barcol hardness).

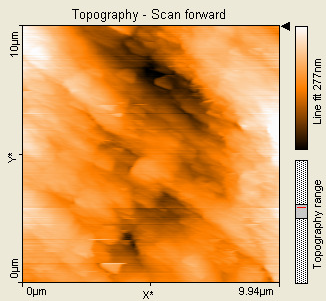

Surace roughness values was measured before and after polishing using Atomic Force Microscopy (AFM). Bis-acryl specimens showed superior surface finish (533.4 ± 110.8 nm) before polishing when compared to that of autopolymerising PMMA (3394 ± 1747 nm). The difference was statistically significant (p-0.021). (Table 5) (Figure 7-10).

Table 5: Analysis of surface finish before polishing (nm).

Figure 7: Bisacryl resin before polishing.

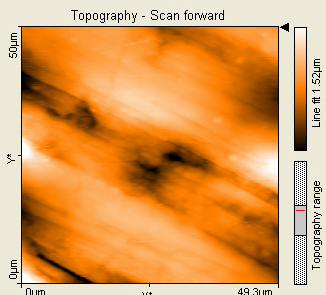

Figure 8: Autopolymerising PMMA resin before polishing.

Figure 9: Autopolymerising PMMA resin before polishing.

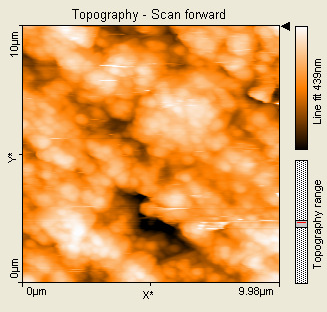

Figure 10: Autopolymerising PMMA resin after polishing.

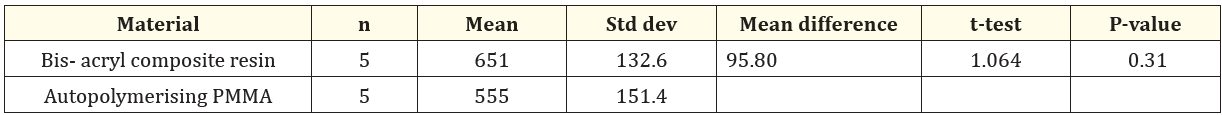

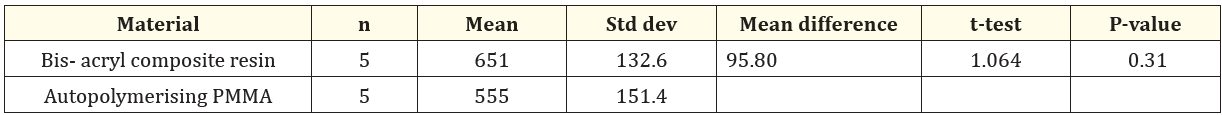

After polishing Bis acryl resins showed increase in surface roughness (651 ± 132.6 nm) whereas the acrylic resin specimens showed good surface finish (555 ± 151.4 nm). However, the surface finish of polished resins did not have statistically significant difference (0.31). (Table 6). When the surface roughness of unpolished Bis-acryl resin and polished auto polymerised PMMA resin were compared, there was no statistically significant difference (p-value 0.80) (Table 7).

Table 6: Analysis of surface finish after polishing (nm).

Table 7: Comparison of surface finish of unpolished Bis-acryl resin and polished PMMA resin (nm).

Two materials which are popularly used in the fabrication of interim fixed restorations were included in the present study viz. tooth moulding auto polymerizing acrylic resin (DPI) and Bis-acryl composite resin (Protemp 3 Garant- 3M). The study compared the following properties viz. flexural strength, deflection, impact strength, hardness and surface roughness.

Many factors have been identified that contribute to the mechanical requirements of the resins used for the fabrication of interim restorations. Significant information is obtained from the invitro studies conducted by different investigators [10]. Composite resins were undergoing significant transformation in the late 1990s. The filler particles were altered to bring in changes in the mechanical properties of the resin and its surface finish. In the earlier phases, comparative studies positioned PMMA superior to composites. Gegauff AG., et al. [10] on comparing the fracture resistance, Bis-GMA composite (1.14 MPa. √m) was found to be intermediate between Polymethyl methacrylate (1.26 MPa √m), Poly R´Methacrylate (0.74 MPa. √m) and epimine resins (1.20MPa. √m). Similar results were found by Koumjian JH., et al. and Osman Yl., et al. [11,12]. Bis-acryl composite resins had started showing promising results in the beginning of the 21st century. Lang et al. showed that Protemp 3 Garant (1015N) had the highest fracture resistance even more than Protemp garant (563N) and other bis-acryl resin composites [13].

According to Craig, flexural strength of provisional composites should fall within the range of 35-70 MPa and that of provisional acrylics should be in the range of 45-80 MPa. In the present study, flexural strength values obtained for Bis-acryl composite resin was 71.6 ± 1.5 MPa and that of autopolymerising PMMA was 49.2 ± 2.17 MPa. These values are comparable to those mentioned by Craig [14].

Flexural strength and deflection of the interim resins are evidently put to test when long span provisional fixed dental prostheses are used. Assessment of mechanical properties is significant in determining the survival of interim restorations under functional forces. How far these in vitro values provide evidence for clinical performance has to be validated through further studies [15]. (Table 1).

Deflection is the movement of a structure when subjected to a load or stress and it is more evident in long span provisional restorations. In the present study, Bis-acryl composite resin showed higher deflection values (5.3 ± 0.2 mm) in comparison to auto polymerizing PMMA (2.9 ± 0.24mm). Assessment of deflection of dental resins has not been exclusively investigated by many research workers. Babcic V., et al. [16] compared deflection of different Bis-acryl composite resin brands. Protemp had showed deflection value of 1.43mm whereas other brands had deflection as follows: Zhermack Acrytemp (1.25 mm), Kaniedenta Kanitemp Royal (1.18mm), DMG Luxatemp-Fluorescence (1.06mm), Voco Structur Premium (1.04MPa) and Dentsply Integrity Fluorescence (0.97mm). Herniandez., et al. [17] have compared the transverse deflection of heat cure and self-cure acrylic resin after a loading of 3500 g. Heat cure resin showed a deflection of 1.250 mm and self-cure resin showed 3.300 mm. In contrast to the results obtained by the other two investigators, the self-cure resin used in the present study exhibited superior resistance to deflection than the Bis acryl resin (Table 2).

In the present study impact strength values of Protemp 3 (0.9 ± 0.3 J) were significantly lower than those of autopolymerising PMMA (1.69 ± 0.57 J). Comparison of impact strength between Protemp 3 and PMMA has not been reported before. Babcic V., et al. compared the impact strength of Protemp with other brands of bis-acryl composite materials where Protemp (15.7 kJ/m2) had shown higher impact strength, in comparison to Voco-structure Premium (8.5 kJ/m2), Zhermack Acrytemp (7.0 kJ/m2), Kaniedenta Kanitemp Royal (7.6 kJ/m2), Dentsply Integrity Fluorescence (8.8 kJ/m2), DMG Luxatemp-Fluorescence (7.3 kJ/m2). Good impact strength enables interim restorations to withstand occlusal loading during mastication for reasonably long period of time [16] (Table 3).

Hardness of a material is indicative of its ability to resist scratch and abrasion. Higher hardness values are required for provisional crowns and FPDs to resist wear. Interim restorations can maintain surface finish during the course of their use, only if the resins have adequate hardness. Maintenance of surface finish is essential to prevent plaque and food accumulation and for successful maintenance of periodontal health.

In the present study, Bis-acryl resin showed higher hardness values (41.6 ± 1.14-Barcol) than auto polymerising PMMA (28.4 ± 1.8 -Barcol). Diaz-Arnold AM., et al. have compared the hardness values of PMMA (15.1KHN) and two brands of Bis-acryl composite resins viz. lntegrity (21.4 KHN) and Protemp Garant (18.6 KHN) and found bisacryl resins superior to PMMA [18]. Astudillo Rubio., et al. have made similar observations on hardness of intermediate restorative resins. Bisacryl resins can resist formation of scratches and thereby discoloration. Newer generations of bisacryl resins will gain greater acceptability than PMMA in the fabrication of intermediate restorations [19,20] (Table 4).

Surface roughness values of unpolished bis-acryIic resin composite were comparable to or superior to polished auto polymerizing PMMA. In an observation made by Gantz., et al. stated that when bisacryl samples were subjected to a conventional polishing system, all of them had roughness values above 0.2 μm (200nm) which is considered as the threshold value of the adhesion of dental plaque [21]. The manufacturers of Protemp-3 do not recommend a polishing system. Polishing is considered as an unnecessary step and it saves considerable time. The results of the present study supports this finding. Surface finish of unpolished Protemp 3 (533.4 ± 110.8nm) was significantly superior to the unpolished autopolymerizing PMMA (3394 ± 1747 nm). Greater surface finish prevents adherence of food debris and plaque and makes the provisional restorations conducive to optimum gingival health. Because of the high surface roughness of unpolished auto polymerizing PMMA, polishing has become a necessary step with PMMA. At the same time both the materials did not show significant difference when conventional polishing was employed. The surface roughness of Protemp was 651 ± 132 nm and that of autopolymerizing PMMA was 555.2 ± 151 nm. By employing a polishing system, surface roughness of bis acryl composite increased from 533.4 nm to 651nm; where as the roughness values of PMMA reduced from 3394 nm to 555nm. This establishes the fact that bis acryl resin does not require polishing and on the contrary PMMA needs a polishing system (Table 5-7).

Bisacryl resin showed flexural strength which is superior to that of autopolymerising PMMA resin. Surface hardness was also superior to that of autopolymerising PMMA.

Deflection of bis acryl resin is comparatively more and its impact strength is less than that of PMMA.

Bisacryl resin does not require conventional polishing and in fact it gets roughened by the polishing.

Autopolymerising PMMA resin requires polishing.

Conceptualization-Navpreet Chhatwal, K. Chandrasekharan Nair; Lab experiments- Navpreet Chhatwal, Review of articles- Navpreet Chhatwal, Initial draft preparation- Navpreet Chhatwal, Jayakar Shetty; Review and editing- K. Chandrasekharan Nair, Supervision K. Chandrasekharan Nair, Jayakar Shetty.

All the authors have read and agreed to the published version of the manuscript.

The authors do not declare any conflict of interest.

Copyright: © 2024 K Chandrasekharan Nair., et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

ff

© 2024 Acta Scientific, All rights reserved.